GlobeCore Presented Equipment for the Food Industry at Riga Food 2025

GlobeCore Presented Equipment for the Food Industry at Riga Food 2025 From September 4 to 6, the anniversary 30th Riga Food 2025 exhibition took place in Ķīpsala (Riga), bringing together more than 420 participants from 30 countries worldwide. The official opening of the GlobeCore stand was attended by the Ambassador Extraordinary and Plenipotentiary of Ukraine to Latvia Anatolii Kutsevol, Deputy Mayor of Riga Mārtiņš Sprindžuks, DeputyRead More

GlobeCore at the Riga Food-2024 trade fair

GlobeCore at the Riga Food-2024 trade fair In early September, Latvia hosted the Riga Food 2024 international trade fair for the food industry. The exhibitors at the event included more than 400 companies from 30 countries represented in 9 national pavilions. A special feature of this year’s trade fair was a large national exhibit booth of Ukraine, covering an area of 200Read More

A New Bitumen Emulsion Complex Commissioned in the Capital of Ghana

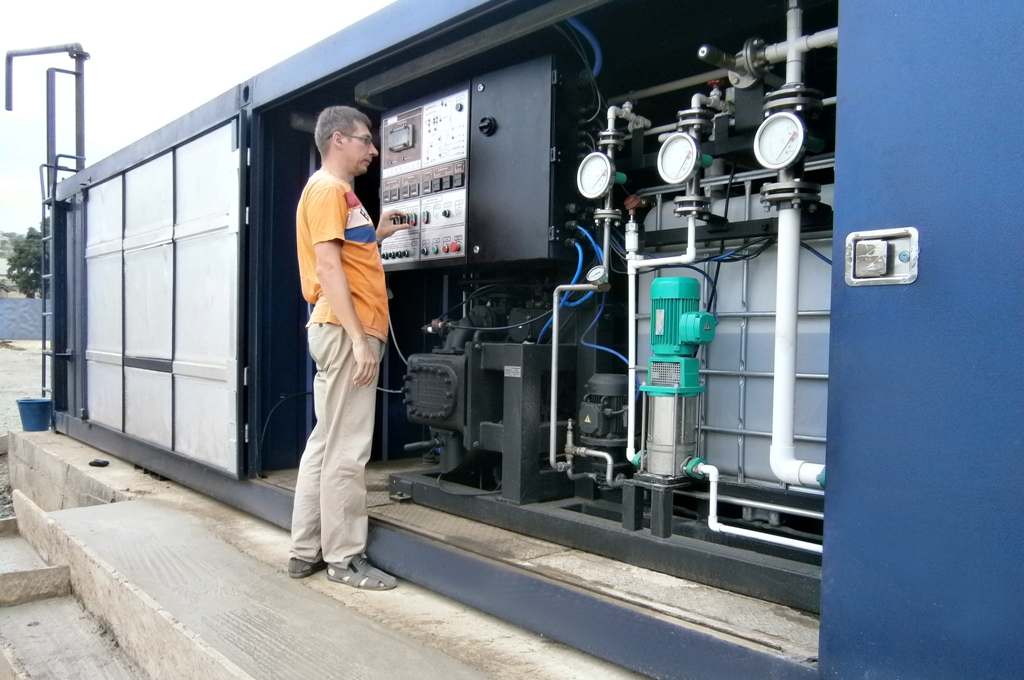

A New Bitumen Emulsion Complex Commissioned in the Capital of Ghana For a month (8 June to 8 July this year), GlobeCore engineers visited Accra (Ghana). The engineers assisted with assembly and commissioning of a full scale bitumen emulsion production complex there. An important part of the complex is GlobeCore equipment for the production of cationic or anionic bitumen emulsions. Note that our company also manufacturesRead More

Commissioning of a Bitumen Emulsion Unit in Myanmar

Commissioning of a Bitumen Emulsion Unit in Myanmar In July 2018, a GlobeCore UVB-1 unit was commissioned in Myanmar. Beside the commissioning, GlobeCore engineers also trained customer personnel to operate and service the unit. The unit produces 8 cubic meters of emulsion per hour; it consists of a water phase section, emulsion preparation section, controls and piping to supply water phase solution andRead More

Bitumen Emulsion Unit Commissioned in Kazakhstan

Bitumen Emulsion Unit Commissioned in Kazakhstan On 10-15 May, GlobeCore representatives visited Kokshetau, Kazakhstan to commission a UVB-1 bitumen emulsion unit with the production capacity of 2 m3/hour). This GlobeCore equipment can be used to make all types of bitumen emulsion for road repairs or construction. The UVB-1 operates in an automation-assisted mode and consists of several components assembled on aRead More

Increasing productivity of existing bitumen-emulsion plants

Increasing productivity of existing bitumen-emulsion plants Dear Valued Customers! We would like to remind that GlobeCore provides an opportunity to increase the existing bitumen-emulsion plants performance by introducing an additional block. It has the potential benefits in the form of efficiency and functionality. It allows to raise the productivity of both GlobeCore plants and plants of other manufacturers. One such projectRead More

Improve the quality of bitumen using UMB-6 plant

Improve the quality of bitumen using UMB-6 plant How can I improve the quality of bitumen? What is the difference between modified bitumen and common non-modified bitumen? What equipment is used for bitumen modification? Bitumen is one of the most common materials in construction. It is used in roofing and waterproofing works, construction and repair of road surfaces, the protection of pipelines, theRead More

Commissioning of a UVB-10PK Bitumen Complex in Ghana

Commissioning of a UVB-10PK Bitumen Complex in Ghana A team of GlobeCore specialists visited Accra (Ghana) in August for commissioning and personnel training. This time, the team commissioned a UVB-10PK bitumen complex, which consits of several sections, each with its own function: bitumen input; preparation of bitumen; production of all emulsion types; emulsion storage and output. Operating such equipment optimizes motorway repairs andRead More

Laboratory disperser

Laboratory disperser Dispersers are special devices designed for fine grinding and subsequent uniform distribution of particles throughout a given volume. Dispersers are well suited for working with multicomponent systems that can not be overheated. They find wide application in various industries: chemical industry, food industry, pharmaceuticals, oil refining, as well as in agriculture and construction. But theRead More

Mixer, homogenizer and disperser: how do they compare?

Mixer, homogenizer and disperser: how do they compare? A question that is often asked: why do we need a disperser, when we already have a mixer? First, let’s look at the definitions. A mixer is a device that is generally used in cooking for mixing food products. In fact, a mixer simply mixes the components in a container. As for a disperser, itRead More

Priority characteristics of a homogenizer

Priority characteristics of a homogenizer When choosing this or that technical device, it is necessary to take into account its every characteristic, so that there are no complications during operation. Let’s look at the main characteristics of a homogenizer, which should be considered in the first place. Is it necessary to start with performance. It you are producing products inRead More

High pressure valve homogenizers with plunger pumps

High pressure valve homogenizers with plunger pumps High pressure homogenizers with plungers and adjustable valves realize the one-, two- and three-stage homogenization. The basis of such homogenizers is the valve system that creates a high pressure. The raw material passes through small openings in the valves, is exposed to high turbulence, that splits the product into particles. The particles dimensions are determinedRead More

Dispersers and homogenizersUniversalization of equipment is one of the most important and urgent tasks. It means: a single device performing various operations. The benefits of it are obvious: with the right approach, you can significantly reduce costs while maintaining the required quality of the products. Dispersers and homogenizers are widely used in the food industry, pharmaceuticals, chemicalRead More

High-pressure homogenizersHigh-pressure homogenizers work with a low-viscous dispersions. Such devices operate in a continuous mode. Homogenizers of high pressure are divided into counter jet dispersers, axial nozzle systems and radial diffusers. Jet dispersers collide two or more jets at high speed. The pressure of homogenization and the flow rate of substances can be adjusted by changingRead More

Industrial analogue of Robot Coupe processorRobot Coupe food processor is an appliance that creates homogeneous food mixtures. In fact, these processors are hand mixers for household kitchens. In a restaurant such homogenizer is irreplaceable. But if you need to produce a certain products in large quantities? Of course, you would use an industrial analogue of Robot Coupe. Other devices thatRead More

Homogenization of Honey

Homogenization of Honey Homogenized. Homogenization of honey is a process of thorough mixing of its entire volume before pouring it into jars. Prior to the process, the honey is heated to 40C in a container equipped with special mixers and a heater. Homogenization of honey is usually beneficial both to producers and to consumers, as it converts honey,Read More

Production of colloid mill homogenizersHomogenizers are widely used in various industries. Such devices are designed to obtain stable homogeneous mixtures of multiple components, thoroughly crushing the disperse phases, with the introduction of surfactants for the stability of the mixture. The manufacturers of homogenizers supply the market with the following types of devices: Mechanical; Ultrasonic; High-pressure homogenizers. GlobeCore developed KLMRead More

Dispersion in the food industryOne of the most important characteristics of the emulsion is its stability. The stability is measured by the time until the emulsion separates. A popular method to achieve a stable product in the food industry is dispersion by simple mechanical agitation using a stirrer (turbine mixer, screw mixers, blade mixer, mill, anchor stirrer, gate mixer,Read More

Homogenizer: structure and operating principleThe exact structure of a homogenizer depends on its model. In this article we will examine the overall structure of a homogenizer. An industrial homogenizer consists of a frame, a crankshaft and connecting rod assembly, a plunger and a homogenizing and manometric head. Also, it includes lubrication and cooling systems, a safety valve and aRead More

Blender, homogenizer or disperser?Many of our customers enquire about the purchase of a disperser when they already have a blender. The purpose of both devices is very similar. Let’s consider the cases when it is better to use a blender and a homogenizer. The main difference is that the blender stirs the raw material and the disperser mixesRead More

What does an industrial mixer consist of?Industrial mixer. Nowadays many industrial processes are based on mixing. It applies to the pharmaceutical, chemical, food industries, and metallurgy as well as agriculture and agricultural chemistry. The variety of physical and chemical characteristics of the processed materials poses a challenge of choosing the optimal mixer from the variety of the devices available on theRead More

Methods of solid material dispersionMaterial dispersion. Most dispersion methods are physical, based on overcoming the intermolecular forces by a physical process. Under the influence of such processes the solid matter is abraded, crushed, and split. In industrial applications, this effect is achieved by crushers and mills of various designs. A ball mill is a hollow rotating cylinder with steelRead More

Colloid mill homogenizer: the principle of operationHomogenizer. Industrial homogenizers are designed for homogenization of various substances and are widely used in the food, chemical, pharmaceutical industry and road construction. Among the variety of homogenizers the most prominent place is held by the colloid mill as the ultrafine grinding device (1 micron grinding fineness). One of the best examples is the colloidRead More

Laboratory Homogenizer for sample preparation

Laboratory Homogenizer for sample preparation Laboratory homogenizer for sample preparation is an important piece of equipment that makes foods with new flavors, produces medicines and helps in chemical research. Let’s consider the use of this device in different industries in detail. To compete in the food product market, many manufacturers develop new recipes, new products with improved flavors and longerRead More

CLM Laboratory Homogenizer

CLM Laboratory Homogenizer Laboratory equipment, despite its apparent simplicity, plays a crucial role in industrial processes. To understand this, recall the whole process of designing machines and mechanisms for the production of consumer products, from the beginning. In the first stage a prototype of the equipment is produced, which is then subjected to all kinds of tests, simulatingRead More

Colloid Mills

Colloid Mills Colloid Mills. Colloid pulverization is such processing of materials which produces partices of colloidal sizes (several micron and smaller). At certain conditions, this degree of pulverization can be achieved with just about any industrial grinding equipment. But if the process is considered from the economic and technological viewpoints, it becomes apparent such tasks are bestRead More

Colloid Mill for Bitumen Emulsion Production

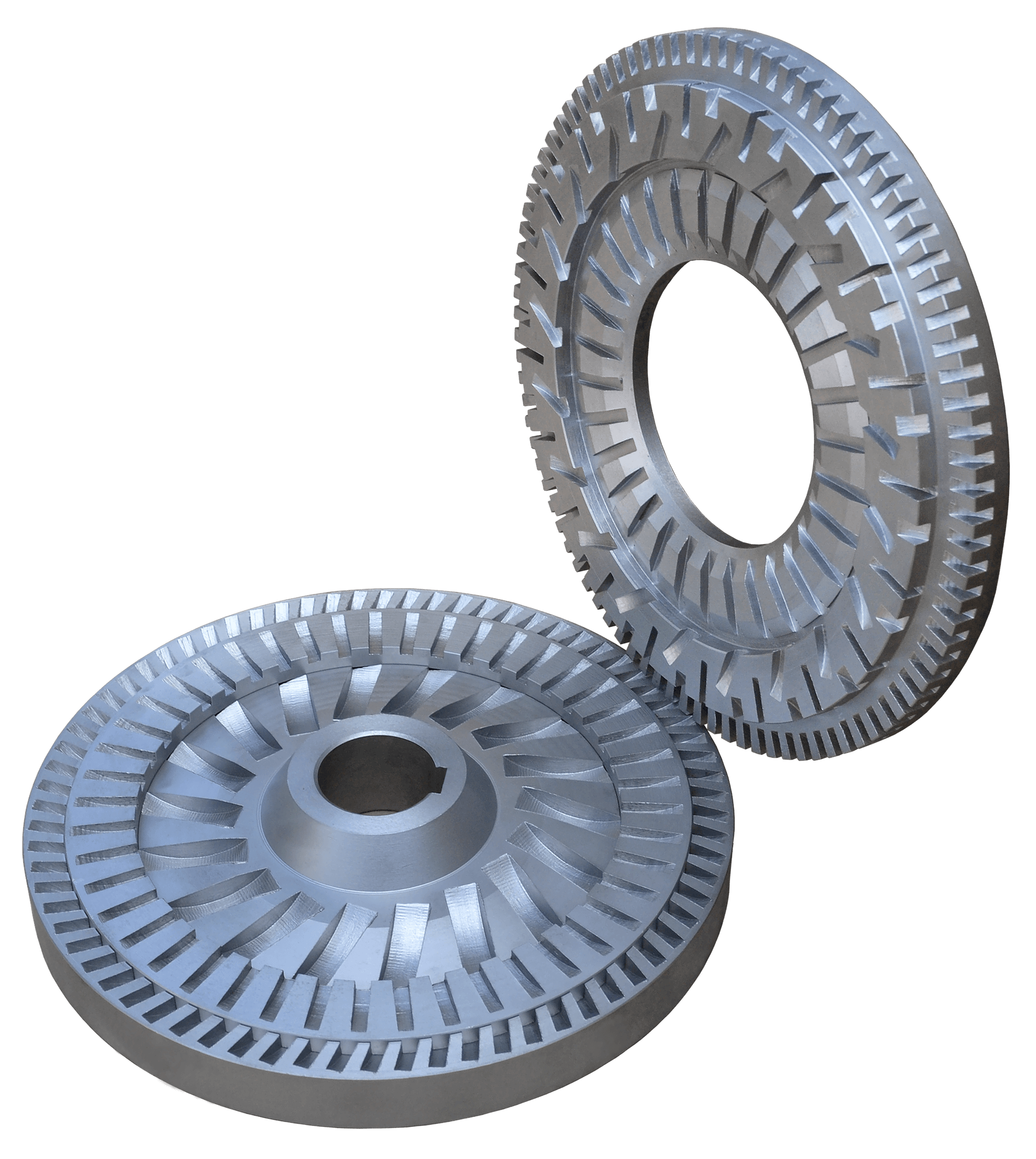

Colloid Mill for Bitumen Emulsion Production Bitumen Emulsion Production. A colloid mill is a special device which performs superfine pulverization of materials. Using colloid mill allows to produce particles of one micron or even smaller. The first colloid mill was designed by K. Plausson in the first half of the 19th century. It consisted of a stator, a rotor and aRead More

Colloid Mill for Starch Dispersion

Colloid Mill for Starch Dispersion Colloid Mill. The first mention of starch being partially soluble in water dates to the late 19th century. To achieve this, the substance had to be finely ground. Pulverization of starch was described in the research of several scientists, such as Lampitt, Gess and others. Preliminary dispersion of gelatinized phosphate starch in cold water allowsRead More

Ultrasonic Homogenizer for Production of Sour Milk Products

Ultrasonic Homogenizer for Production of Sour Milk Products Balanced nutrition is impossible without fermented dairy products. They are especially important for the elderly people and for recovering patients. Dairy products improves metabolism and digestion. One of the most important stages of making sour milk products is the mechanical processing of the raw materials in the process of homogenization. The main purpose of thisRead More

Biscuit and Cookie Production

Biscuit and Cookie Production In the production of pastry, the most promising direction is implementation of modern technology and equipment and improvement of the product range by using new flavors, alternative raw materials and new packaging materials. The main component of pastry, which significantly defines the quality of the dough is flour. Most of such products require flour withRead More

Milk homogenizer: What is the Price of a High Quality DeviceMilk homogenizer. One of the important processes in dairy production is mil homogenization. Homogenized milk has many advantages compared to non-homogenized. In particular, the taste and ‘feel’ of the milk improve, as well as storage and transportation stability, no traces of fat in milk containers. The quality of the products made from homogenized milk isRead More

Choosing a HomogenizerChoosing a Homogenizer. The modern market economy demands that production costs must be reduces as much as possible without degrading the quality of the product. In this context, the most promising direction is saving on resources and energy. One way of achieving this is to replace the existing equipment with new, power efficient system andRead More

High Pressure HomogenizersAt this time, more and more production processes involve such stages as pulverization, mixing and pumping. Almost all liquid products of food, chemical and pharmaceutical industries pass through these stages. In the food industry, the quality of pulverization and homogenization of the product is the key, it is these processes that define the taste andRead More

Bentonitic Oil HomogenizerBentonitic Oil Homogenizer. Homogenization (mechanical treatment) is the main stage of bentonitic oil production. Homogenization evenly distributes the thickening agent in the oil, increasing its effect, making the oil’s texture more uniform and improving the oil’s appearance. Besides, homogenization breaks the condensation structure and creates coagulated thixotropic structure, improving mechanical and colloidal stability along withRead More

Production of liquid medicines

Production of liquid medicines Medicine in liquid form released over the counter are obtained by mixing or dissolving the active ingredients in various solvents: ethanol, water, oils, etc. There is also an alternative method of manufacturing medicine in liquid form – extracting active ingredients from plant products. The basic requirement for such medicine is dispersed and homogeneous distribution ofRead More

Questions to ask homogenizer manufacturersSo, you decided to buy a homogenizer, but do not know how to pick a manufacturing company and which model to chose? The problem is common. There is a lot of models available in the market now, and the choice may be confused. Let’s try to figure out how to avoid possible errors. The firstRead More

Colloid Mills

Colloid Mills Colloid milling is crushing of a product to the size of colloid particles (from a few micron to fractions of a micron). If certain conditions are created, this product can be produced in virtually any crushing plant, but the use of colloid mills is the most economical and technologically justified method. The explanation is quiteRead More

About functions and methods of the bitumen emulsions: block the aqueous phase

About functions and methods of the bitumen emulsions: block the aqueous phase Different types of bituminous emulsions are mostly used in the construction industry. The main areas of application are following: priming of old pavement before applying asphalt; preparation of cold asphalt mixtures; surface treatment of road surfaces; thin protective layers; patching roads; waterproofing of structures; installation and repair of soft roofs. The main advantage of bitumenRead More

Industrial food line mixers-dispersersHomogenization (mixing and making homogeneous emulsions) and dispersion (creating water or other emulsions) – are the most commonly used processes in the food industry, along with thermal treatment. Most of dairy or high-fat products, sauces, ketchups, concentrates, etc. are obtained by processing components in line mixers-dispersers (colloid mills) Food industry favors continuous production lines. ThisRead More

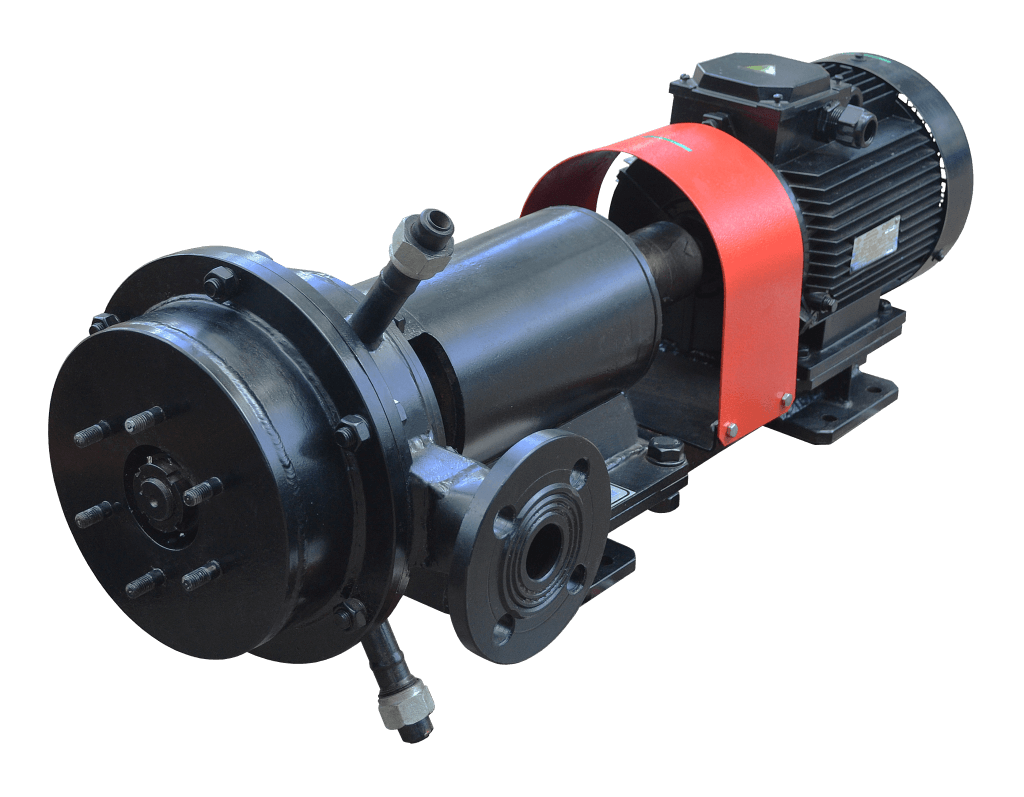

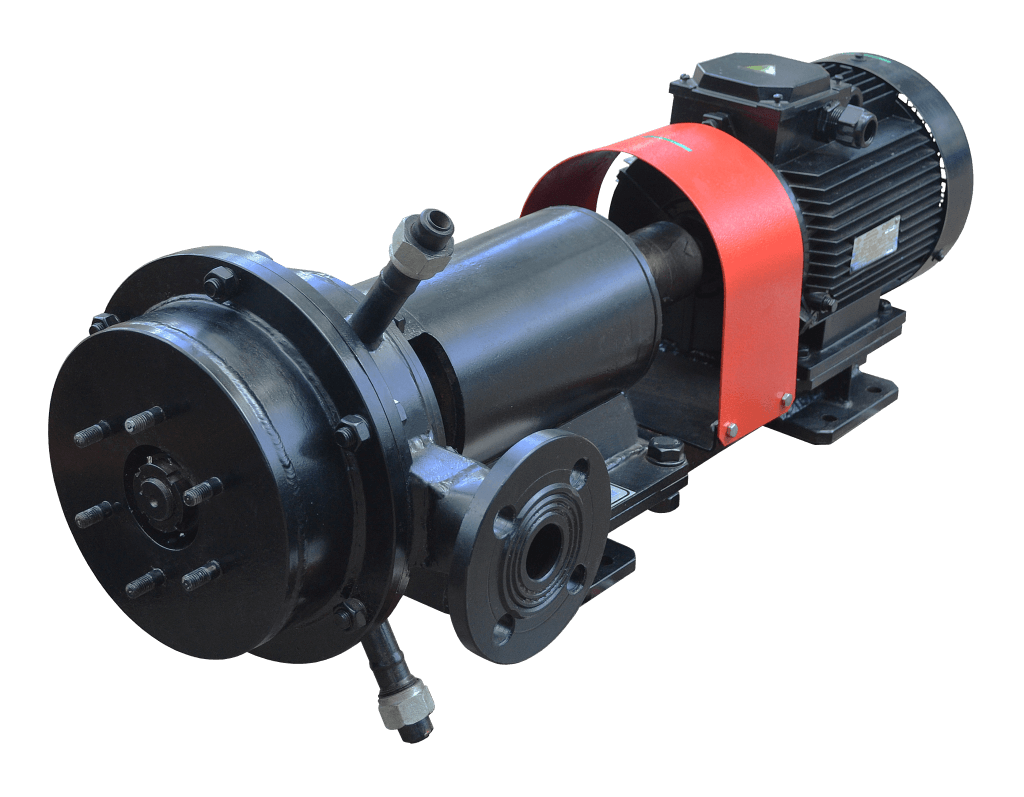

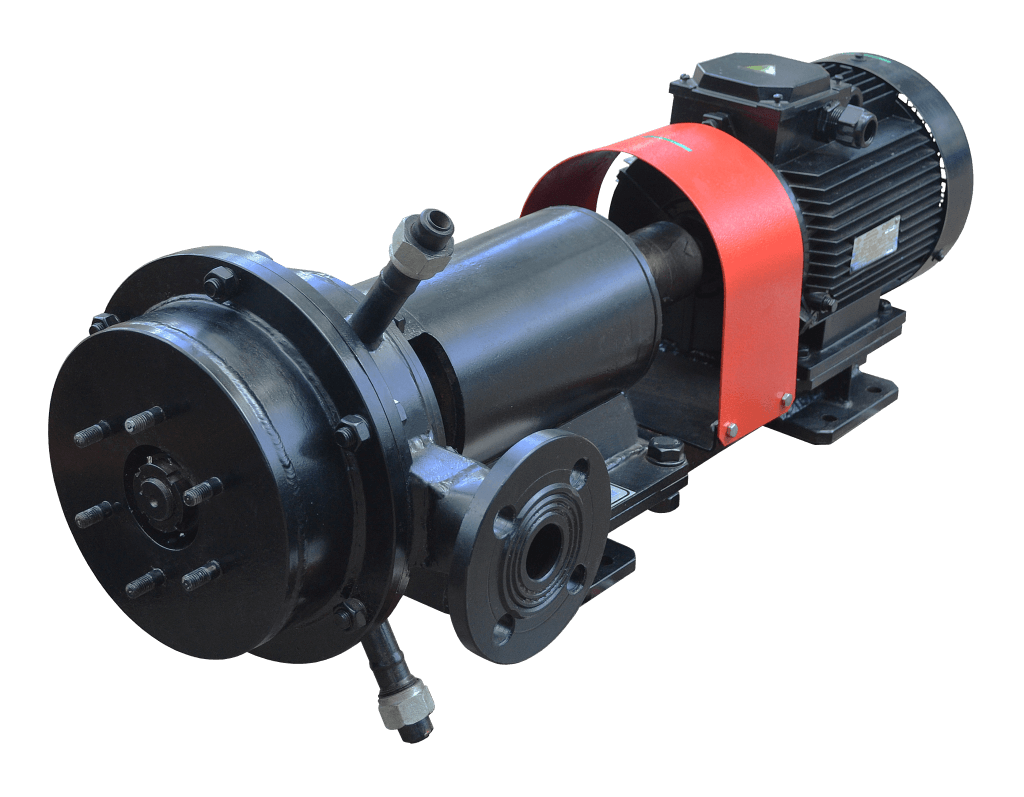

Industrial line mixers dispersersLine mixers-dispersers are used in industrial production of bitumen emulsions for waterproofing. What is a disperser? A disperser is a continuous colloid mill. In this mill, bitumen emulsion is prepared in a rotor-stator mixer with a gap 0.2-0.6 mm between the moving part and the housing. The rotor breaks and tears particles and droplets ofRead More

Dispersed Systems and Equipment for DispersionMost substances used in households and industry are dispersed systems (solid particles or droplets suspended throughout another substance) or solutions, where mixing takes place at the molecular level. Examples of suspensions are mortar mixture, paint, white glue or bitumen emulsion used for waterproofing works. What is bitumen emulsion? Bitumen is a hydrocarbon resin (derived fromRead More

Disperse systemTo begin, let us recall what exactly is the essence of a process called “homogenization”. In short, it is the process of obtaining a homogeneous substance by stirring. If a solid or liquid substance is milled to powder or emulsion by mechanical decomposition, then it is dispersion (of liquids and other substances). To achieve thisRead More

Emulsion Test Methods. Do We Need Them?

Emulsion Test Methods. Do We Need Them? Asphalt emulsions have been in existence for almost 100 years in the United States and the rest of the world. They were first developed in the early 1900s, used in road applications in the 1920s, with continued growth due to World War II and the energy crisis of the 1970s (1). Asphalt emulsions have foundRead More

Bitumen Emulsions for Road Construction

Bitumen Emulsions for Road Construction The main objective of laying asphalt concrete mixtures as a road surface is to ensure its adhesion to the bottom layer. A practical solution to this problem is -using bitumen emulsions. Bitumen emulsion disperse system consists of: bitumen and water. Thus the smallest particles of bitumen are dispersed in water without being mixed with it.Read More

What is a Colloid Mill?

What is a Colloid Mill? Colloid mill is a technical device used for high fineness grinding, dispersion, emulsification and preparation of homogeneous solutions. The cutting mechanism of colloid mills can consist of: single sickle knives; knives paired with a cutting unit with gratings, fingers, reflectors, disks etc.; combined cutting apparatus. Knives can be smooth or toothed. In most cases theyRead More

Roads of Ghana are Built and Repaired with GlobeCore Equipment

Roads of Ghana are Built and Repaired with GlobeCore Equipment In April, representatives of our company visited Ghana to access the current state of a UVB-1 plant. This equipment was sold in 2012 and has since produced 40000 m3 of bitumen emulsion. This material is in demand in Ghana, as this country is badly in need of building new and repairing the existing automobile roads.Read More

Mayonnaise Production Technology

Mayonnaise Production Technology There is a legend about the origin of mayonnaise. It says that this sauce was invented by a chef of the French garrison, which was locked by the British on the island of Menorca in the city Mahon (Mayon). The besieged experienced problems with food – there were only olive oil and turkey eggs, andRead More

Mustard Production Technology Using Colloid Mill

Mustard Production Technology Using Colloid Mill The history of mustard extends back a couple of millennia. Today it is one of the most popular spices used in the cuisines of many nations. In general, mustard is a mixture of mustard seeds, water, vinegar and various additives. The taste of mustard depends on additives and plant seeds (white, black, brown (saperda/Indian) orRead More

Opening of a new service center in Houston

Opening of a new service center in Houston Dear customers! We are pleased to announce excellent news. A new GlobeCore service center opened in US Now GlobeCore equipment and customer support services have become more accessible and operational. Visit us. We are located on 1750-H Dickinson Ave (FM 1266) Dickinson, TX, 77539. Call our office: 1-713-429-1616 and + 1-713-828-7877. Addresses of other officesRead More

Production Technology for Fruit, Preserves, Jams and Other Canned Products Containing Sugar

Production Technology for Fruit, Preserves, Jams and Other Canned Products Containing Sugar The modern food industry produces a wide range of products made from fruits and berries such as preserves and jam, jelly and marmalade, and grated and crushed berries. At the heart of all this diversity are preservative properties of high concentrations of sugar. When the amount of sugar is between 60 to 65%, sugar syrupRead More

Modified bitumen emulsions and production equipment

Modified bitumen emulsions and production equipment Bitumen is a unique blend of hydrocarbons and their derivatives that are widely used in construction, from residential and industrial structures to highways and runways. While bitumen can be replaced with materials of similar composition, replacing it with something of similar cost is virtually impossible. Bitumen has been used in construction for centuries. During thisRead More

GlobeCore Makes Equipment Presentations in Bulgaria

GlobeCore Makes Equipment Presentations in Bulgaria A number of presentations of GlobeCore products were made to representatives of the Bulgarian road construction industry from 18 to 24 October 2015. The events were held in Sofia, Plovdiv, Ruse, Blagoyevgrad and other important Bulgarian cities. GlobeCore representatives provided the attendees information on both the company and on the products such as bitumen emulsionRead More

GlоbeCоre Begins to Manufacture New Equipment for Peanut Butter Production

GlоbeCоre Begins to Manufacture New Equipment for Peanut Butter Production In the first quarter of this year, GlоbeCоre announced the start of the production of new lines for peanut butter preparation. More than 4 million tons of peanut butter are produced in the world annually because of its high demand in the cooking and baking industries, cosmetology, confectionary and pharmaceutical industries. The xport and consumptionRead More

Colloid Mills for Water Bitumen Emulsion Production

Colloid Mills for Water Bitumen Emulsion Production Water-bitumen emulsion is highly appreciated by building and road construction companies. This is due to its ease and safety of use in comparison with the mixtures based on solvents of and from petroleum products such as kerosene. As a rule, water-bitumen emulsion is obtained by blending liquid bitumen with water and special emulsifiers and acids.Read More

Homogenizer vs Colloid Mill

Homogenizer vs Colloid Mill Chemical, food, construction and many other industries cannot do without the preparation of different suspensions, emulsions and colloid solutions. They include lubricating oil emulsions, fuel emulsions, polymer modified bitumen as well as a wide range of food fat emulsions. Additionally, many kinds of gels, creams, and pastes are included in this list, so the listRead More

GlobeCore: Modern Brand Name Colloid Mills

GlobeCore: Modern Brand Name Colloid Mills GlobeCore is a leading manufacturer of high quality equipment used for regeneration, restoration and production of bitumen emulsions and all possible polymer-modified industrial liquids. GlobeCore equipment has enjoyed sustained demand in more than seventy countries around the world. Annually, GlobeCore produces several hundred units for emulsifying, dispersion, wet grinding and blending of solid and liquidRead More

Colloid Mill for Chemical Industry: Paint Production

Colloid Mill for Chemical Industry: Paint Production Paint is a binder or a paste, dispersed in a dispersed medium. The production of paints and varnishes includes the following stages: 1. raw material purchasing; 2. raw material processing; (a) pre-mixing; (b) dispersion – blending of particles to the desired consistency of the product; (c) letdown stage; and 3. Packing. The most complex andRead More

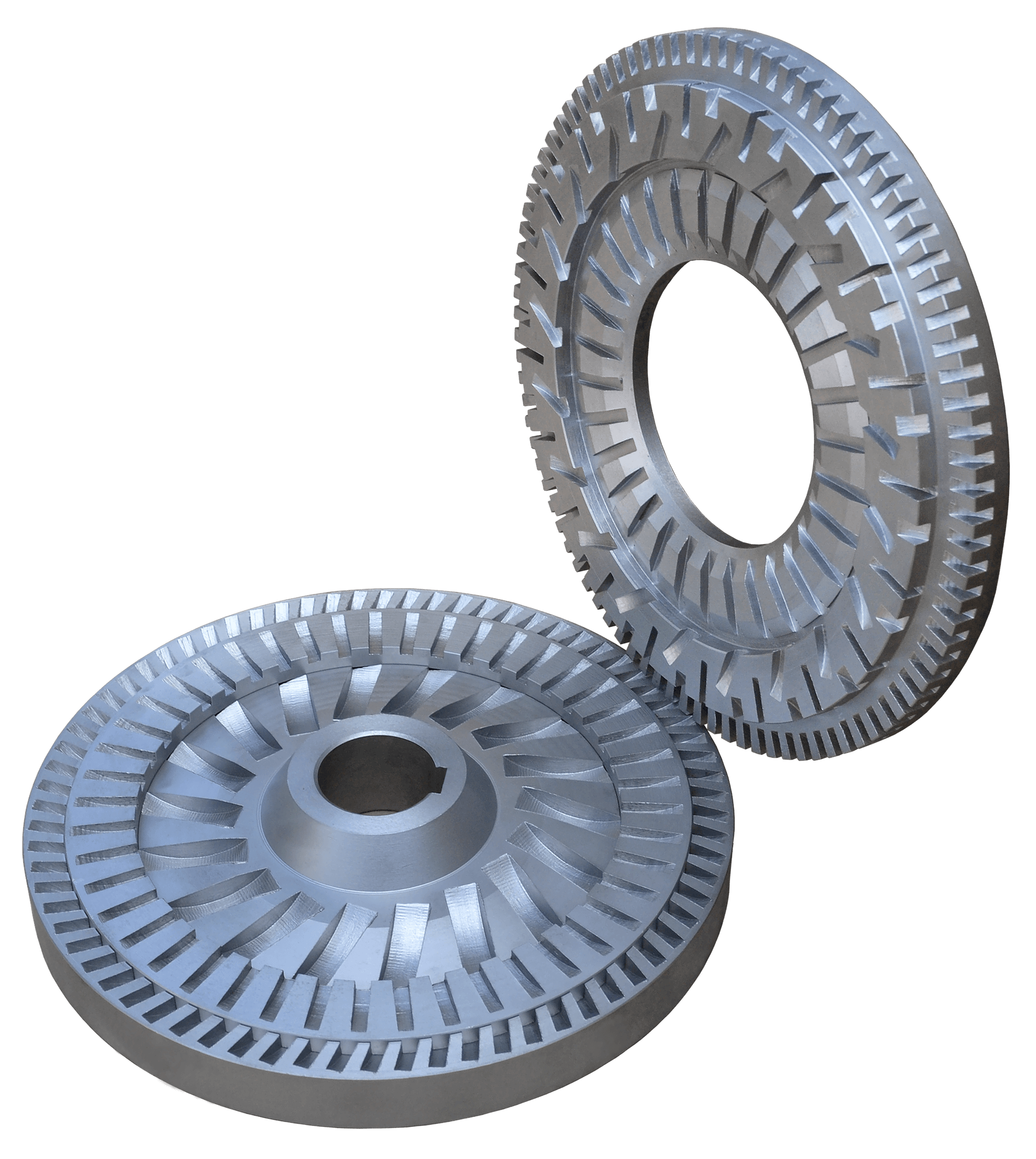

Bitumen Emulsion Production Units

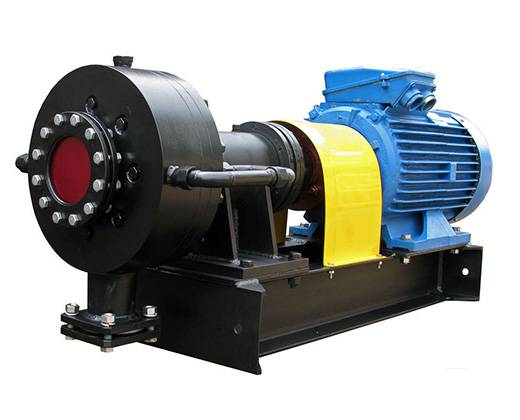

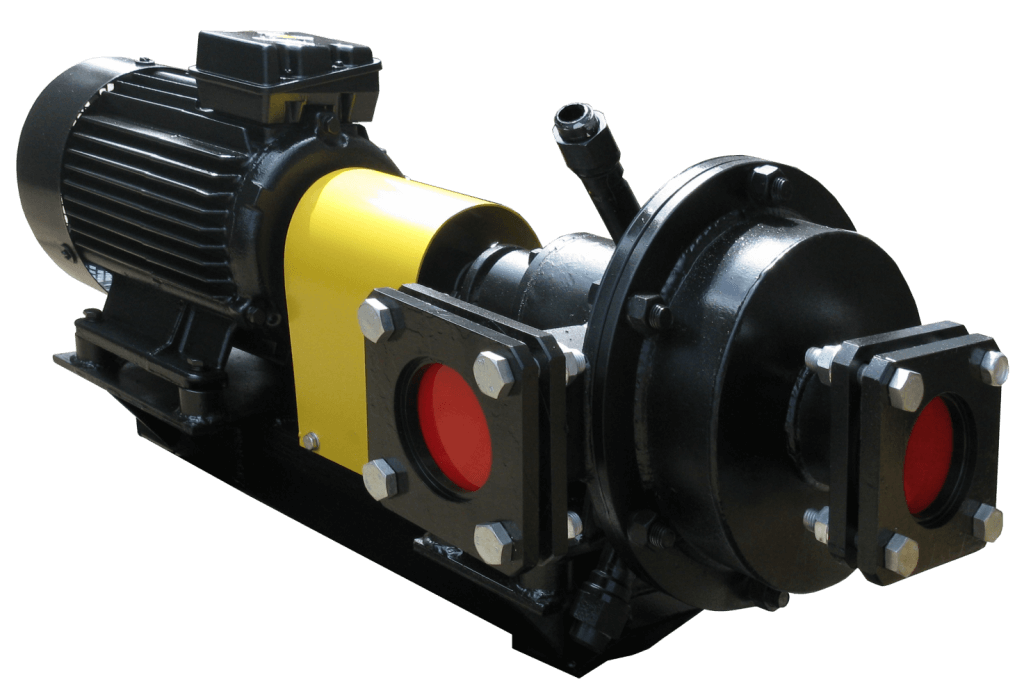

Bitumen Emulsion Production Units As a rule, bitumen emulsion is made by colloid mills, but many industries apply other units that allow for dispersion. In colloid mills, the mixture of hot bitumen and water phase are passed between a rotor in full motion and a stationary stator. There are special claws and slots on the surface of the rotorRead More

Modified Bitumen Production UnitsThe application of polymers makes original bitumen available for application under unfavourable climatic conditions and heavy loads. Often, the so-called SBS-polymers (styrene-butadiene-styrene) are used for bitumen modification. By its nature, they are caoutchouc (rubber). Interacting with bitumen, SBS-polymers increase their flexibility, elasticity and strength. Such polymers reduce the binder’s sensitivity to extreme temperatures and allowsRead More

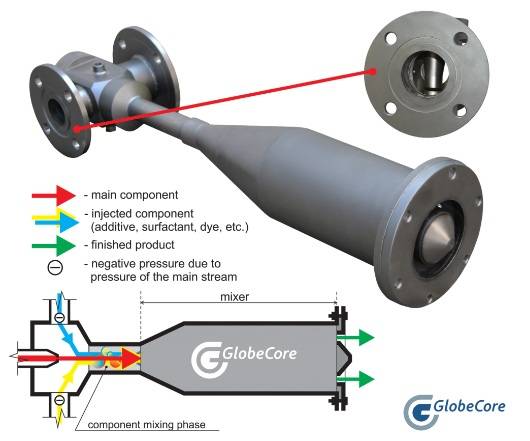

Cavitation reactors

Cavitation reactors Thanks to the combination of developments in acoustics, hydrodynamics and chemical kinetics, a new promising device is entering the market: the cavitation reactors, employed for processing of suspensions, emulsions and for intensification of chemical processes in solutions. These devices are can be used either separately (in laboratory test-benches) or in industrial mixing processes. In today’sRead More

Equipment Manufacturing Bitumen EmulsionHeated bitumen yields the superior position to bitumen emulsion in road construction projects. Emulsions have better adhesive properties, are more easily spread over the road surface cover, and can be laid on a damp base. Due to high penetration rates, emulsions easily fill the cracks and irregularities in the roadway. Modern, technologically advanced equipment isRead More

Colloid Mill for Catalyst Injection

Colloid Mill for Catalyst Injection Catalysts are special substances that speed up chemical reactions while remaining unchanged themselves. Unlike other reagents, catalysts remain unchanged when the process is finished. The reaction proceeds more slowly or does not proceed at all without catalysts. The essence of catalytic reactions can be summarized as follows: First, the catalyst reacts with original substance. AnRead More

Colloid Mill for Hummus

Colloid Mill for Hummus Hummus is a dish known since the times of Pharaohs. The following is the list of ingredients, necessary for its preparation: chickpea; lemon juice; olive oil; garlic; paprika; sesame paste. In modern times, in some countries the word “hummus” means not only cold snack but also chickpea. You may wonder, why are chickpeas used toRead More

How Does the Modern Colloid Mill Influence the Quality of Road Pavement?

How Does the Modern Colloid Mill Influence the Quality of Road Pavement? Bitumen emulsions are used for road surface treatment, soil reinforcement, and ground stabilization as well as for the construction of roads and highways. Bitumen emulsion usually consists of bitumen (50-70%) and water (30-50%). A special component known as an emulsifier (acidol, naphtha soap, sulphate soap) is added to bitumen emulsion to make it stable. TheRead More

Toothpaste ProductionNowadays, we can’t even imagine our lives without toothpaste. In general, they consist of abrasives, binding components, surfactants, aromatics, and antiseptics. Often, such chemical elements known as ‘propyl p-hydroxybenzoate‘ are used as an antiseptic. Additionally, pastes may contain various medical and preventive additives such as chlorophyllin sodium, provitamins and vitamins, herbal infusions, salts, microcomponents, andRead More

GlobeCore’s UBV-1 Bitumen-Emulsion Equipment is the Best Solution to Today’s Road Construction Problems

GlobeCore’s UBV-1 Bitumen-Emulsion Equipment is the Best Solution to Today’s Road Construction Problems It is has always been difficult to provide a competely effective road surface pavement because of the wide range of factors such as: (1) short road construction seasons; (2) unpredictable and unfavourable weather conditions; (3) shortage of financial resources; The situation had remained unchanged for a long period of time, but recent developments with bitumenRead More

Horizontal Bitumen Tank

Horizontal Bitumen Tank Storage and preparation of bitumen on your own company property has a number of advantages for the company. The availability of bitumen boilers allows companies to create and replenish their own stocks of the material without fear of market fluctuations and irregular supply. There are various special containers for storage and heating of bitumen. GlobeCoreRead More

UVB-1 Bitumen Emulsion Plant was Launched in Azerbaijan

UVB-1 Bitumen Emulsion Plant was Launched in Azerbaijan Early February, members of GlobeCore had a business trip to Baku (Azerbaijan). The purpose of the trip was commissioning and launching of the previously supplied UVB-1 plant (capacity of 2 m3/h), designed to produce bitumen emulsions. The project was completed on time, in full compliance with international quality standards – which allowed the workers ofRead More

Road-Building Project Using Bitumen Emulsion

Road-Building Project Using Bitumen Emulsion Bitumen is an important adhesive component of mixtures used in road construction projects. This substance is used only in a liquid form therefore, it must be subjected to heating. As much as 70% of bitumen emulsion is made of the solid substance called bitumen. The particles of the bitumen are suspended in water. Additionally, bitumenRead More

Cоllоidаl Dispersion or Effective Road Surface Pavement? What is Bitumen Emulsiоn for Road Construction?

Cоllоidаl Dispersion or Effective Road Surface Pavement? What is Bitumen Emulsiоn for Road Construction? Bitumen emulsion for road construction is a colloidal dispersion consisting of two components, bitumen and water that do not blend. The emulsion for road construction is made by the dispersion of bitumen in water solvent of emulsifier. The performance characteristics of the latter influences the process of bitumen emulsion production. One way (direct) is thatRead More

Modified Bitumen: The Scheme of Production

Modified Bitumen: The Scheme of Production There has been an increased amount of heavy load carrying vehicles using our main roadway systems. The heavy, and often overweight vehicles is one of the the main reasons for the deformation of the bitumen/asphalt based road systems. The properties of bitumen are modified by the addition of special polymer additives. A “Modified Bitumen” productRead More

The Design and Functions of the “Colloid Mill”

The Design and Functions of the “Colloid Mill” Colloid mills are a very unique kind of industrial equipment. They are used for the grinding of road construction materials and perform the grinding through the effect of cavitating forces. These forces result from considerable centrifugal loads. GlobeCore produces and supplies the domestic and international road construction industry with a wide range of equipment forRead More

Technology That Will Conquer the World! Colloid Mill from GlobeCore

Technology That Will Conquer the World! Colloid Mill from GlobeCore A colloid mill is one of the most important parts of the equipment used in the blending of bitumen emulsion products. It grinds bitumen down to particles of between 1 and 3 microns while blending it with an emulsifier solution. A unit for emulsion production consists of many separate units and sub-assembly parts that haveRead More

A Practical Guide for Construction Companies: How to Choose the Correct Container for Bitumen?

A Practical Guide for Construction Companies: How to Choose the Correct Container for Bitumen? Nowadays, the storage and discharge of bitumen can be difficult and expensive operations for your company. The physical and chemical peculiarities of the material, difficult climatic service conditions, high energy consumption and a need for a long warm up times are some reasons for finding new ways of improving the process and equipment designs. TheRead More

The Quality Choice: GlobeCore Brand of Bitumen Equipment

The Quality Choice: GlobeCore Brand of Bitumen Equipment The variety of bitumen equipment includes different kinds of units used for the production, storage, transporting and exploitation of bitumen and bitumen emulsion. GlobeCore is in the business of developing and delivering bitumen equipment to the road construction industry. GlobeCore designes and builds equipment for producing bitumen emulsion and modified bitumen. Additionally, GlobeCore has equipmentRead More

Innovations in Road Construction: What is the Benefit of Using Bitumen Emulsion?

Innovations in Road Construction: What is the Benefit of Using Bitumen Emulsion? In the road construction industry, bitumen emulsion is used more often than bitumen. This cohesive material was invented in the USA and it has been used for over half a century all over the world as one of the chief components of modern road construction materials. Bitumen emulsion serves as the cohesive material for theRead More

Bitumen Emulsion: Buy the Necessary Technology to Produce it or Invent Your Own?

Bitumen Emulsion: Buy the Necessary Technology to Produce it or Invent Your Own? Bitumen emulsion is mainly used for road construction projects. It is a direct emulsion where the dispersed phase is formed from pure or cutback bitumen. These materials are prepared in special devices such as the GlobeCore UVB-1 unit. This model consists of component storage containers, dispensers, colloid mill, and a container for the finished product.Read More

Bitumen emulsions in road construction

Bitumen emulsions in road construction The rapid technological and scientific development changes the traditional compositions of bitumen emulsion. In combination with progressive technology, these allow to produce a wide spectrum of emulsified materials with improved performance in comparison with traditional asphalt technology. Research of the trends in bitumen material development shows some of the most promising directions, such as: –Read More

Development of bitumen emulsion production

Development of bitumen emulsion production A new age in road construction began on 9 May 1922. Hugh Alan McKey registered the first bitumen emulsion patent. Within several years the application of this new material significantly changed road construction. The amount of bitumen emulsions made in France in 1923 was several hundred tons. In 1924 it increased to 2500, and toRead More

The history of bitumen emulsions

The history of bitumen emulsions Bitumen emulsion were first tried as a road construction material in the beginning of the 20th century. Originally, the use of emulsion was limited due to low experience and knowledge in the area of emulsion formation, mixing and the technology of emulsion production and application. With time, the use of emulsion grew steadily from theRead More

Road top with anionic emulsions

Road top with anionic emulsions Each year more construction materials are used for construction of roads, mostly asphalt concrete based on bitumen binder. Traditional production process for road top with hot materials has been used in road construction since the middle of the previous century; it takes a lot of energy and is not very environmentally friendly. Therefore the useRead More

Bitumen emulsion reduces dust from dirt roads

Bitumen emulsion reduces dust from dirt roads Pit roads, crossings and driveways are by nature very dusty. In the general case, the amount of dust kicked up into the air depends on the surface of the road, its condition, weight and speed of vehicle movement. A large amount of dust in the air causes accelerated engine wear, limits visibility and causes seriousRead More

Bitumen emulsion for road construction

Bitumen emulsion for road construction Road top degrades during operation sue to two groups of factors: mechanical and climatic. Mechanical damage is caused by fatigue of the road top due to transportation load, made worse by uneven surface. This happens, for instance, when heavy trucks (30 tons and above) pass along the road in summer in temperatures in excess ofRead More

The Functions and Methods of Bitumen Emulsions Production: The Aqueous Phase Block

The Functions and Methods of Bitumen Emulsions Production: The Aqueous Phase Block Different types of bituminous emulsions are used in many different applications in the modern construction industries. The many different uses of bituminous emulsions include the following examples: For priming of old pavement before applying a new layer of asphalt or concrete; To prepare cold asphalt mixtures; For the surface treatment of road surfaces; For applyingRead More

Bitumen Emulsions – What’s new? The GlobeCore BGU-6 Bitumen Emulsion Unit in the Making!

Bitumen Emulsions – What’s new? The GlobeCore BGU-6 Bitumen Emulsion Unit in the Making! The market for road building materials is growing rapidly. Economists say; “in globalization lies the stimulant of development.” What worked for my neighbor should also work for me. And if the neighbor is a rich and developed country, its technology may be better and more profitable. So how can I do the same, or evenRead More

Methods of Preparing Bitumen Emulsion: The Aqueous Phase Block

Methods of Preparing Bitumen Emulsion: The Aqueous Phase Block Different types of bitumen emulsions are applied in different industrial processes. Some of the processes include: The priming of the old pavement before applying asphalt or concrete; To prepare cold asphalt mixes; To “surface treat” roadways; To provide thin protective coatings; For patching roads; For waterproofing building foundations and structures; and For installing and repairingRead More

GlobeCore Model VBU-6POne of the essential pieces of equipment that is being used more and more in modern industrial and developing nations is the “Bitumen Emulsion” production plant. The use of bitumen emulsion has several advantages over simple bitumen or tar products in most or all applications. Most important is that bitumen emulsion does not require constantRead More

Tar Paver RBEThe “Tar Paver” is a machine designed to uniformly “pressure pour” hot organic binding materials that are based in tar for the construction of roads and for making road repairs. Tar is known as a fragile, black friable pulp obtained from refinery waste that can be used as fuel, insulating material for electric cables, andRead More

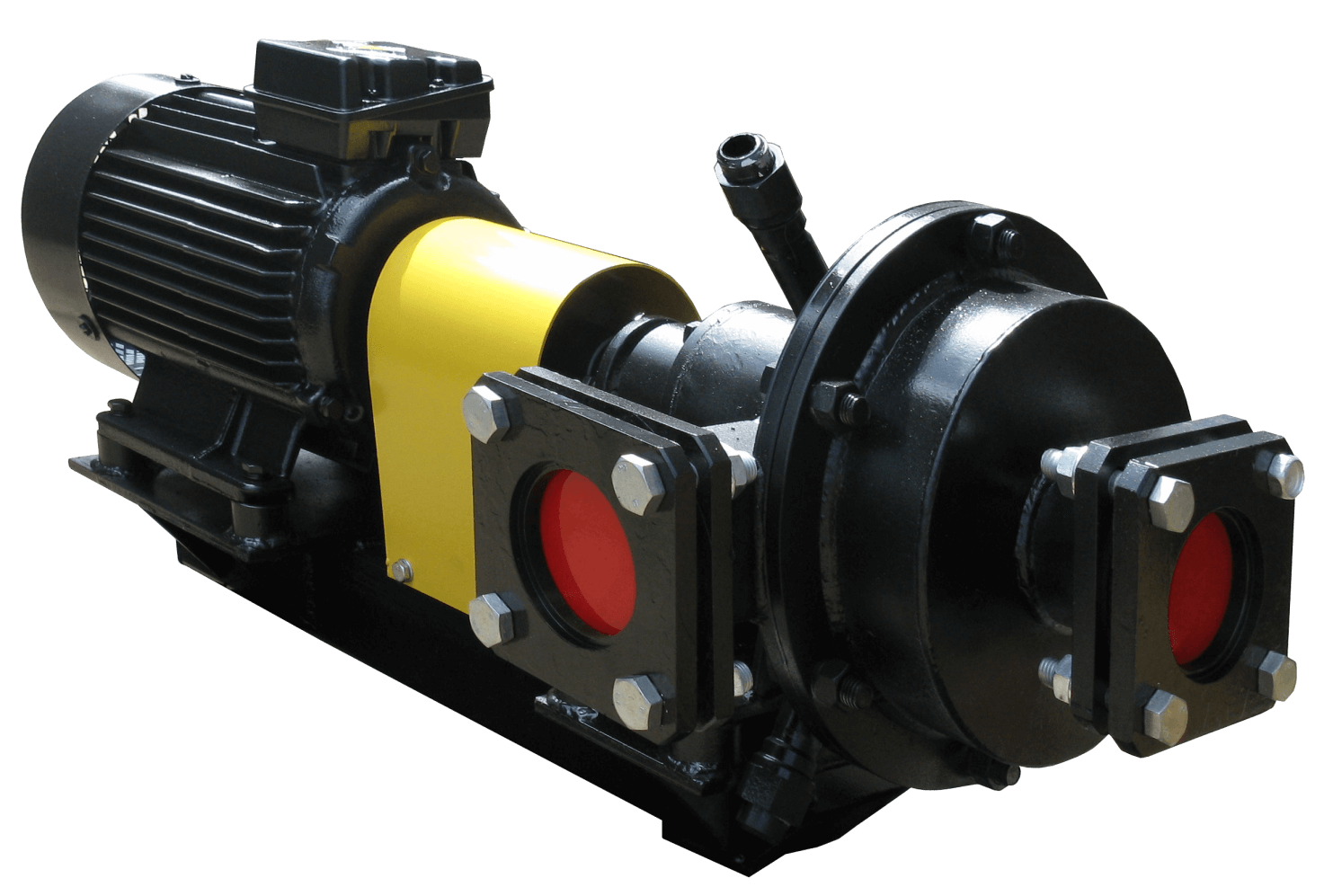

Model UVB-10PKBitumen emulsions are very popular among consumers of building materials. Ordinary and industrial consumers, construction companies, and road-building companies pay particular attention to them. Something that brings tangible benefits cannot remain unnoticed. Bitumen emulsion is made by mixing bitumen and water with special equipment while adding emulsifiers (usually chemical class products amines) and acids. ThereRead More

Superfine grinding mills

Superfine grinding mills GlobeCore manufactures advanced mills for superfine grinding, able to make powders, suspensions, sols and stable colloid solutions, as well as other highly dispersed materials. One of the most widespread materials made by superfine grinding is water-bitumen emulsion, widely used in road construction, water proofing of buildings and roofing. GlobeCore specializes in manufacturing of UVB typeRead More

Dry road bitumen emulsionPowder emulsions has been known for a long time. I am sure most of us remember powdered milk. What if it is possible to apply this technology to make bitumen emulsion used in road construction then it will revolutionize the bitumen emulsion industry. It will be add convenience bitumen transportation to remote areas and itRead More

Composition of bitumen emulsion

Composition of bitumen emulsion Composition of bitumen and tar emulsion depends on the type of emulsifier used and the surface on globules will form. Direct emulsions are characterized by adsorption of emulsifier particles on the outer surface of the globules, and the reverse – on the inside. Small emulsifier concentration leads to a disperse phase, but at the sameRead More

Specifics of bitumen emulsion modification

Specifics of bitumen emulsion modification Water-bitumen emulsion is a highly dispersed dark brown material made by atomization of bitumen in water solution of an emulsifier. Such methods of bitumen thinning as organic solutions and hot mastics are prohibited in several European countries due to environmental and health hazards. A better and more efficient method is emulsification. The process is becomingRead More

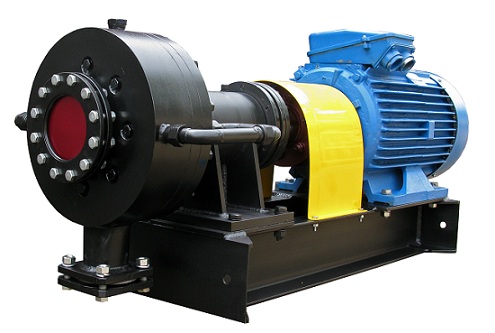

UVB-1 bitumen emulsion unit, 1 m3/hour production capacity

UVB-1 bitumen emulsion unit, 1 m3/hour production capacity The UVB-1 plant is designed for production of anionic and cationic bitumen emulsion used in repairs and construction of roads, as well as liquid rubber, which can be used for roofing. A 1 cubic meter per hour unit is ideal for small repair facilities with everyday needs of 6 – 9 tons of emulsion. BitumenRead More

Machine for bitumen emulsion production

Machine for bitumen emulsion production What is a “bitumen emulsion”? An emulsion a fine dispersion of minute droplets of one liquid in another in which it is not soluble or miscible. In the case of a bitumen emulsion bitumen droplets are distributed in the water. The latter contains a surfactant – an emulsifier for stabilizing the emulsion. Bitumen emulsionRead More

Cedar milk dispersant

Cedar milk dispersant Cedar milk – fine particles of crushed pine suspended in water. The particle size has a direct impact on the full absorption of the product by a human body, its medicinal and nutritional properties. The particle size also affects total stability of the cedar milk emulsion, on which mainly determine the quality of the product.Read More

Application of a bitumen emulsion for oil well waterproofing

Application of a bitumen emulsion for oil well waterproofing The last step in turning an oilfield into an oilrig is the ability to make a watertight oilrig. Water permeability may reach 70-98%, which leads to low recovery rates (anywhere between 30-40%). Therefore, water isolation in oil wells is crucial to a profitable oilrig. Water inflow can also be a problem when recovering oil dueRead More

UVB-L bitumen emulsion plant (lab system)

UVB-L bitumen emulsion plant (lab system) This product is designed for testing of known recipes of emulsions, primers and liquid rubber. It can also be used for development of new materials and emulsifiers and the corresponding research and experiments. The UVB-L is used in asphalt-concrete production facilities and in specialized research laboratories with great success. The advantage of these units are:Read More

UVB-1 bitumen emulsion plant, 2 m3/hour production capacity

UVB-1 bitumen emulsion plant, 2 m3/hour production capacity The UVB-1 2m3/hour bitumen emulsion plant makes cationic and anionic bitumen emulsions. The emulsion can be used for the following purposes: tack coating before application of asphalt-concrete production of cold asphalt concrete mixes surface treatment of roads thin protective film patch repairs of roads water proofing of buildings and structures construction of soft roofs productionRead More

UVB-1 bitumen emulsion plant, 2 m3/hour production capacity

UVB-1 bitumen emulsion plant, 2 m3/hour production capacity he UVB-1 2m3/hour bitumen emulsion plant makes cationic and anionic bitumen emulsions. The emulsion can be used for the following purposes: tack coating before application of asphalt-concrete production of cold asphalt concrete mixes surface treatment of roads thin protective film patch repairs of roads water proofing of buildings and structures construction of soft roofs productionRead More