Colloid milling is crushing of a product to the size of colloid particles (from a few micron to fractions of a micron). If certain conditions are created, this product can be produced in virtually any crushing plant, but the use of colloid mills is the most economical and technologically justified method.

The explanation is quite simple. Particles of colloidal size tend to gravitate to each other, after which they stick together or are compressed by external forces. To prevent this phenomenon, colloidal milling should be done in the presence of some dispersing medium. After milling, colloidal particles grow apart at a distance where the attracting force is weaker than wedging force of dispersion medium. Liquid is considered the best dispersion medium of today, while gas is used less frequently.

In most cases, wet-type colloid milling is used. The ratio of solid and liquid phases of the system depends on the material which is being milled and can range from 1:2 to 1:6.

The main difference between colloidal systems and molecular solutions lies in their heterogeneity. Impossibility of dissolving the dispersed phase in the dispersing medium is one of the key quality requirements of colloidal milling.

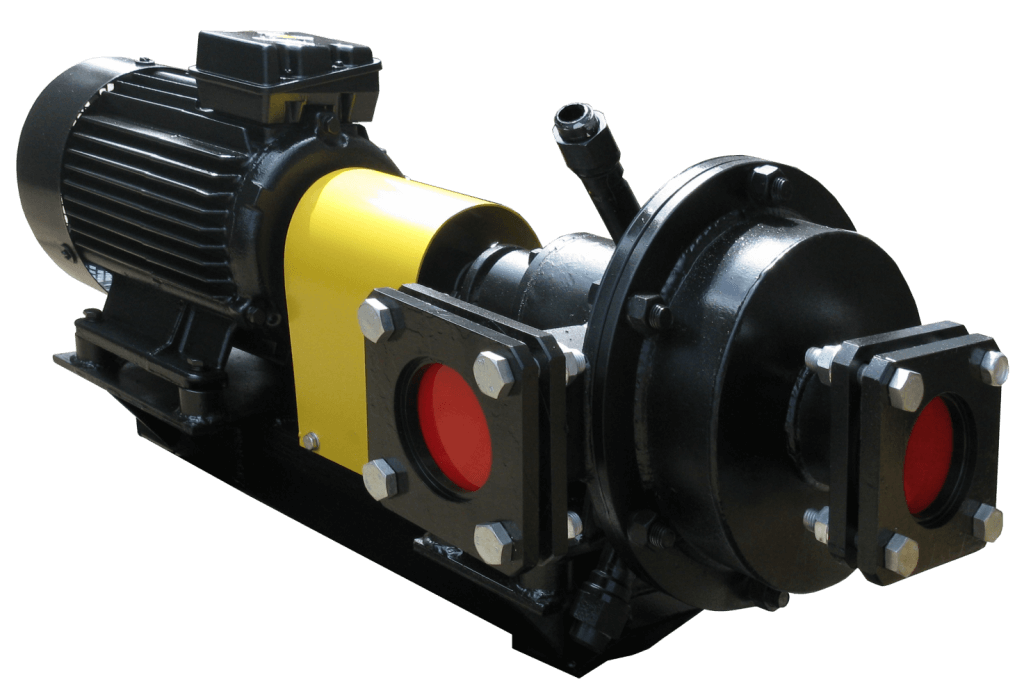

GlobeCore company produces high quality colloidal mills for grinding raw materials for chemical, construction, engineering and oil industries. Furthermore, GlobeCore colloid mills are used in equipment designed for producing bituminous emulsions and modifying of bitumen with polymers.