Colloid mills are a very unique kind of industrial equipment. They are used for the grinding of road construction materials and perform the grinding through the effect of cavitating forces. These forces result from considerable centrifugal loads.

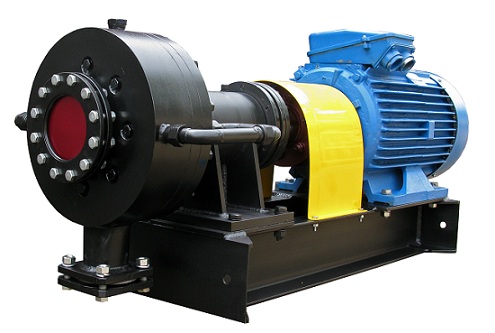

GlobeCore produces and supplies the domestic and international road construction industry with a wide range of equipment for the production of bitumen emulsions and modified bitumen products. The GlobeCore brand of equipment may vary from simple colloid mills to complex systems for blending operations. The grinding process in the colloid mills is performed by friction or blows. This process is performed either dry or wet.

The colloid mills, that use a wet grinding process, consist of a body with a tapered seat in the middle of the mill. Inside the seat there is a rotor fixed on a vertical shaft that rotates with a speed of between 1,800 and 7,500 revolutions per minute (RPM).

The liquid runs through a special opening and flows between the tapered seat and the rotor. The solid particles wear down and go out together with the liquid through an outlet hatch. A micrometer screw regulates the gap between the seat and the rotor. The micrometer screw helps to regulate the size of the gap needed for grinding the polymer so there is sufficient homogenization of the final product. Grinding of the solid particles in the colloid mills is performed due to shear pressures created by the liquid films. These films of liquid are formed on the moving and unmoved smooth surfaces of the rotor and the seat.

Additional functions of the colloid mills may include modern optional features that supplement the standard features of the plant. For example, they might include a semi-automated operating system of the bitumen content in the emulsion, a system of heating and preparation of soap solutions, and different levels of process automation with input lines for additional components.

Moreover, the GlobeCore colloid mills guarantee a high quality level of grinding and homogenization of the final product at attractive prices. Additionally, GlobeCore provides you with qualified technical assistance at all levels of the sales and service processes.