Material dispersion. Most dispersion methods are physical, based on overcoming the intermolecular forces by a physical process. Under the influence of such processes the solid matter is abraded, crushed, and split.

In industrial applications, this effect is achieved by crushers and mills of various designs.

A ball mill is a hollow rotating cylinder with steel or ceramic balls inside. The grinding is achieved by the rotation of the cylinder, and the rolling balls crushing the processed material. The main drawback of a ball mill is that the size of the resulting particles are of a fairly wide range, from 2 to 70 microns.

A vibrating mill is a hollow cylinder with a circular oscillatory movement, where the material is rapidly crushed under the influence of a complex movement of balls.

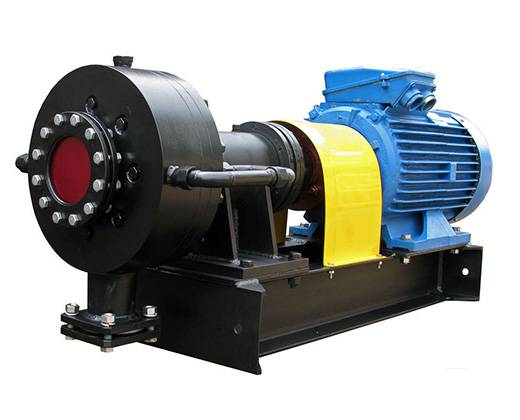

A colloidal mill is a device which allows to achieve smaller sizes of particles. The principle of operation of such devices is based on the impact fracturing the particles by centrifugal forces, as they pass through the gap between the rotor and the stator.

Dispersion of the resulting product is determined by the gap width and the rotational speed of the rotor: the higher the speed and the smaller the gap, the higher is the dispersion.

There are also ultrasonic dispersion methods. Ultrasonic cavitation generates shock waves that destroy the processed material. The resulting particle size depends on the frequency of the ultrasonic vibration. The effectiveness of the ultrasonic dispersion increases considerably with pre-grinding of the material.