Products

News & Publication

-

GlobeCore Presented Equipment for the Food Industry at Riga Food 2025

9.29.2025

From September 4 to 6, the anniversary 30th Riga... Read More -

GlobeCore at the Riga Food-2024 trade fair

9.26.2024

In early September, Latvia hosted the Riga Food 2024... Read More -

A New Bitumen Emulsion Complex Commissioned in the Capital of Ghana

8.5.2019

For a month (8 June to 8 July this... Read More -

Commissioning of a Bitumen Emulsion Unit in Myanmar

7.17.2018

In July 2018, a GlobeCore UVB-1 unit was commissioned... Read More

-

Laboratory disperser

5.3.2017

Dispersers are special devices designed for fine grinding and... Read More -

Mixer, homogenizer and disperser: how do they compare?

5.3.2017

A question that is often asked: why do we... Read More -

Priority characteristics of a homogenizer

5.3.2017

When choosing this or that technical device, it is... Read More -

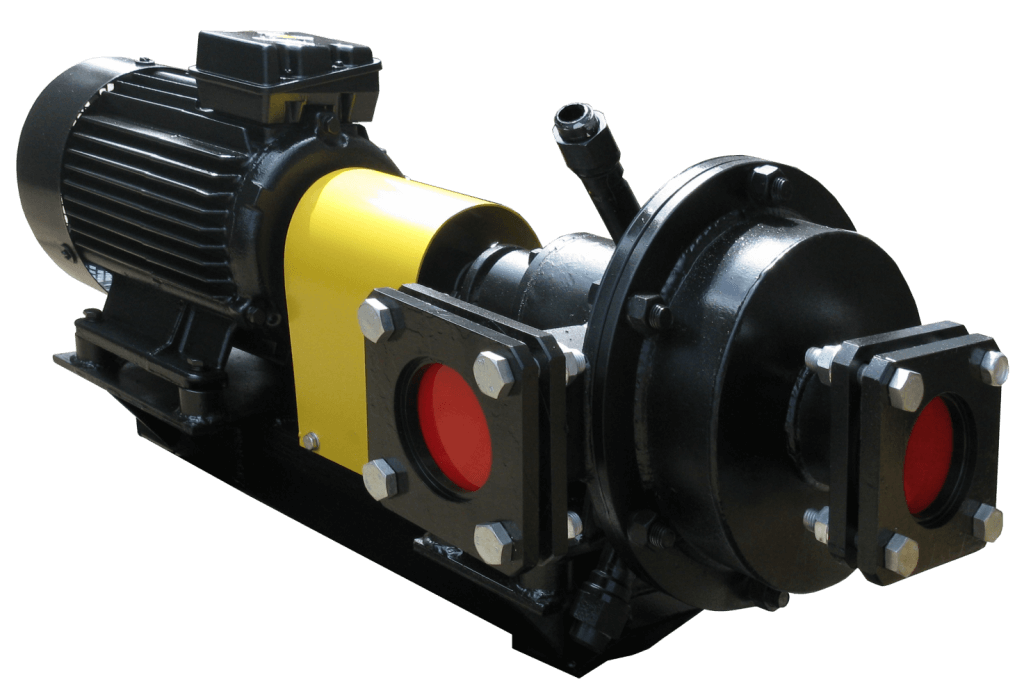

High pressure valve homogenizers with plunger pumps

5.3.2017

High pressure homogenizers with plungers and adjustable valves realize... Read More

-

Laboratory Homogenizer for sample preparation

1.13.2017

Laboratory homogenizer for sample preparation is an important piece... Read More -

CLM Laboratory Homogenizer

1.13.2017

Laboratory equipment, despite its apparent simplicity, plays a crucial... Read More -

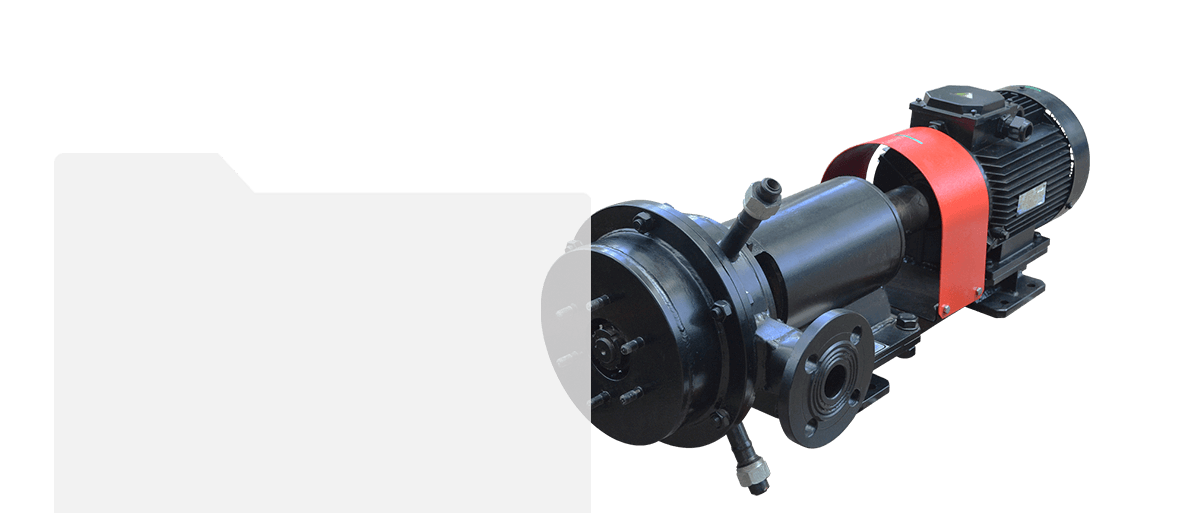

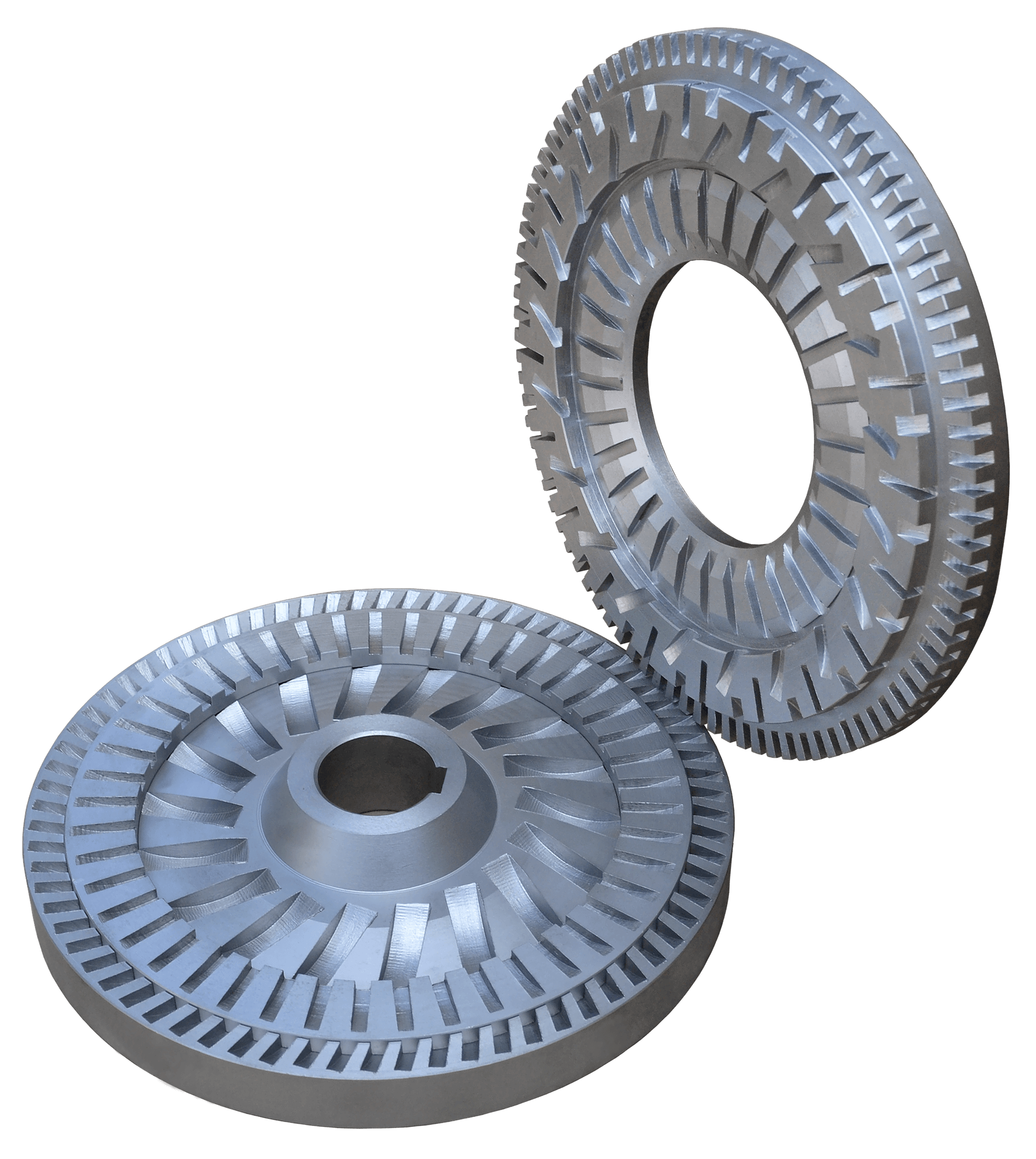

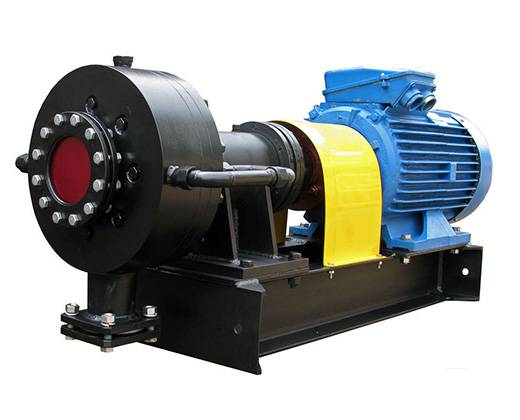

Colloid Mills

1.6.2017

Colloid Mills. Colloid pulverization is such processing of materials... Read More

Globecore Video Chanel

About GlobeCore

About GlobeCore

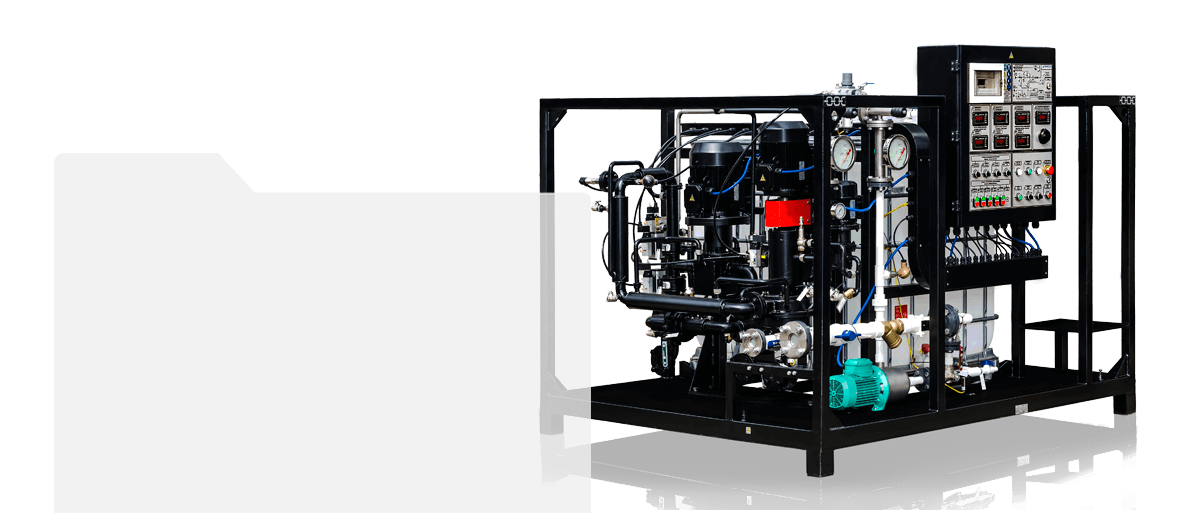

GlobeCore is one of the world leaders in industrial manufacturing. Products of GlobeCore are used in transformer oil purification and degassing, insulation oil filtration, oil reclamation, and power transformer vacuuming.

The head office and production facilities are located in Poltava, Ukraine. Our systems have been supplied to and are successfully operated in more than 100 countries. A global network of over 100 dealers supports equipment sales and services worldwide.

GlobeCore has established representative offices in the United States, South Africa, and the United Arab Emirates to extend reach and improve efficiency. We actively expand production and sales territories, develop our infrastructure, and introduce new services.

The production facility is equipped in compliance with international industry standards: it features robotic plasma metal cutters, automated welding systems, and modern PLC-controlled machinery.

The engineering staff systematically develops new oil purification equipment and improves existing product lines. GlobeCore manufactures hundreds of units annually, with each product thoroughly tested at the company’s own testing facility.

Hundreds of positive letters and comments from our clients confirm that we are moving in the right direction. Over the years, we have established numerous contacts and built a vast network of returning customers. And we are not stopping. GlobeCore is open for new opportunities and invites everyone to visit our facility in Poltava.