Milk homogenizer. One of the important processes in dairy production is mil homogenization. Homogenized milk has many advantages compared to non-homogenized. In particular, the taste and ‘feel’ of the milk improve, as well as storage and transportation stability, no traces of fat in milk containers.

The quality of the products made from homogenized milk is much higher. That is why homogenization became a must in most processes to make milk, dairy products, ice-cream, cheese etc.

Due to the development of homogenized component technology, the requirements to product dispersion are high. The main problem of making fine emulsions are the limited capabilities of homogenizers. Development of devices and methods to make finely dispersed emulsion with the ability to adjust dispersion and with high capacity, is rather important.

To homogenize milk and dairy products, valve homogenizers are mostly used. But analysis of valve homogenizer designs shows that there are significant flaws: large size and weight, high material and energy costs, rapid wear of the valve and a high price tag. Other types of homogenizers either fail to achieve the required degree of fat dispersion, or have significant disadvantages in use.

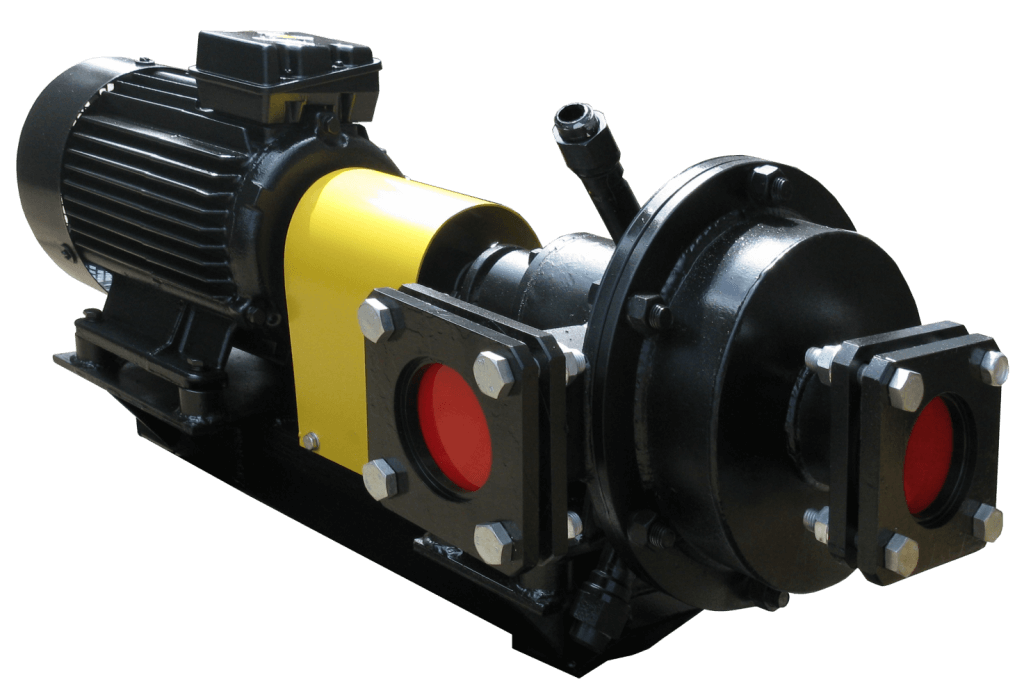

GlobeCore offers food production businesses homogenizers for milk processing with improved characteristics. We can manufacture a device based on your individual specifications for your production line. If necessary, GlobeCore specialists will visit the site, set up the production line and commission it. The “homogenizer prices” issue will be a thing in the past after you see our homogenizers in action!