The UVB-1 plant is designed for production of anionic and cationic bitumen emulsion used in repairs and construction of roads, as well as liquid rubber, which can be used for roofing. A 1 cubic meter per hour unit is ideal for small repair facilities with everyday needs of 6 – 9 tons of emulsion.

Bitumen emulsions were first used in Europe in the 1930s. Since then, the industry has seen many promising designs, which allowed to improve production efficiency and process, as well as product yield. At this time, bitumen emulsions of all types (anionic, cationic, water in oil, oil in water, fast, medium and slow setting) are without a doubt a promising material for various construction works. The number of processes where bitumen emulsions are used is growing. Application of these materials is highly profitable and reliable Количество технологических процессов, при которых в той или иной степени используются битумные эмульсии, неуклонно растет.

Plants developed and manufacture by GlobeCore are highly efficient and feature high quality. The use of innovative technology saves user costs, at the same time ensuring the following:

- Reliable component parts;

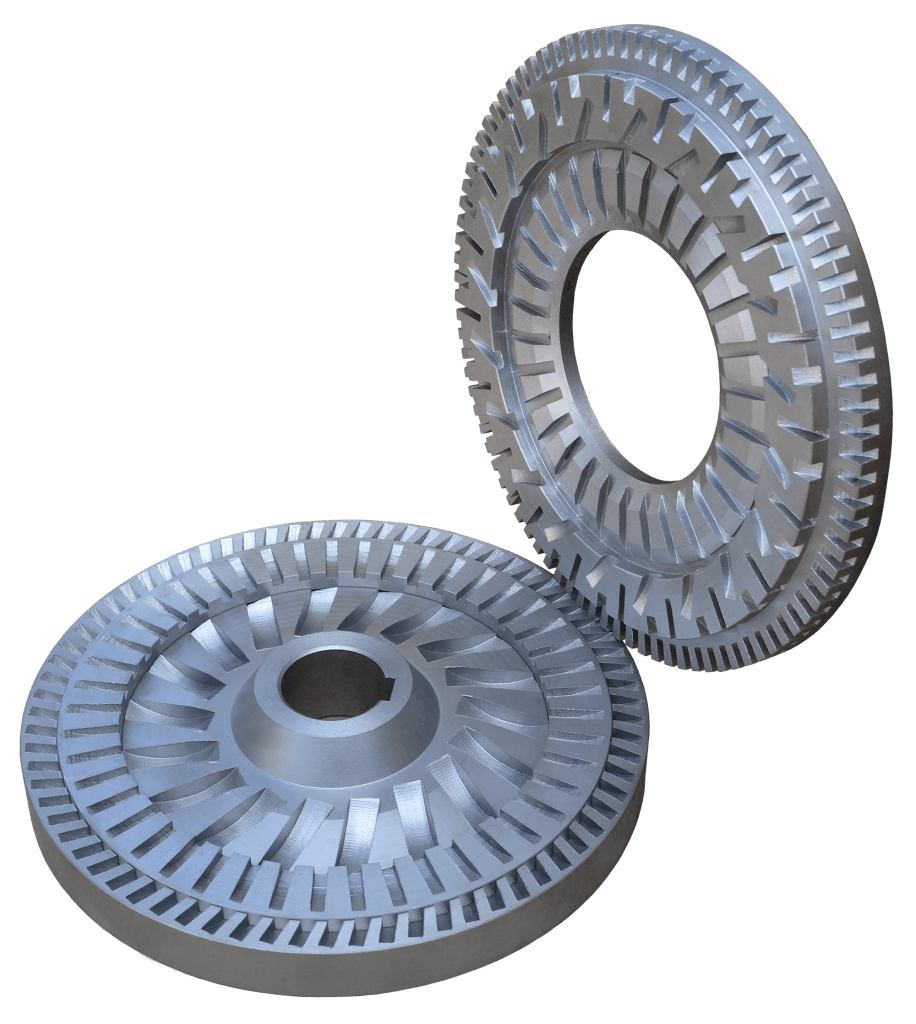

- High quality of the product. The use of hydrodynamic mixer along with a colloid mill makes finely dispersed emulsions possible. Such product is in full compliance with industry standards, in many case exceeding their requirements;

- Automatic or semi-automatic control of the plant;

- Precise portioning of water phase and unique blending technology;

- customization;

- spare part depositories and worldwide customer support.

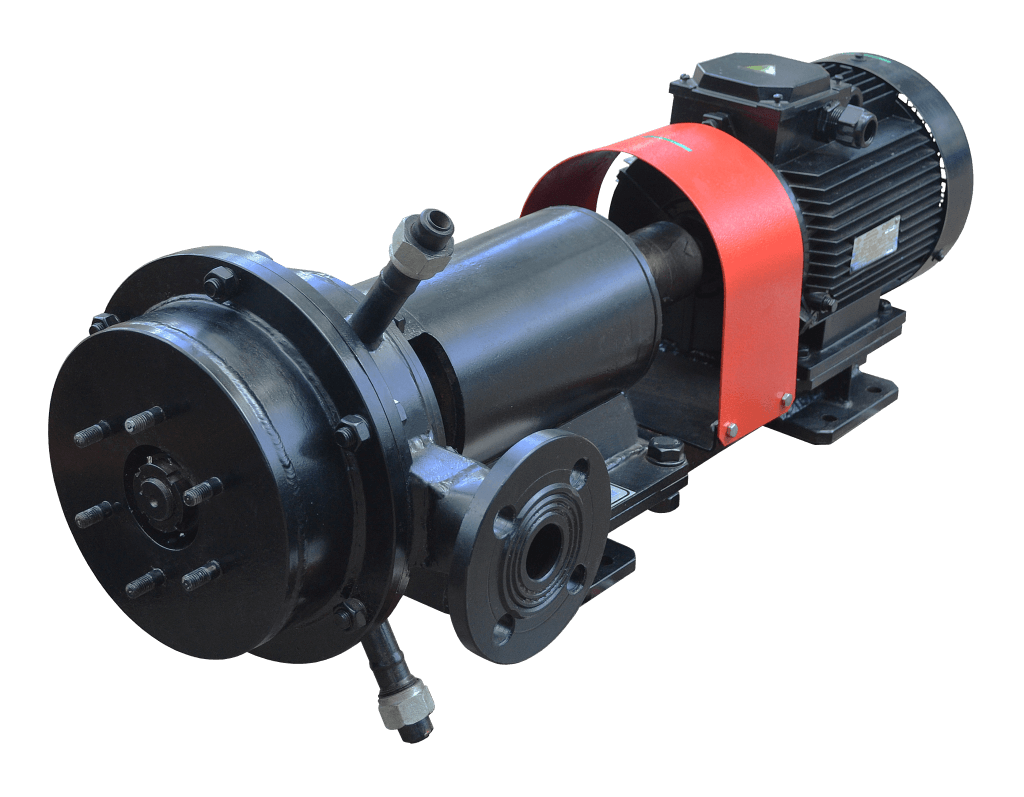

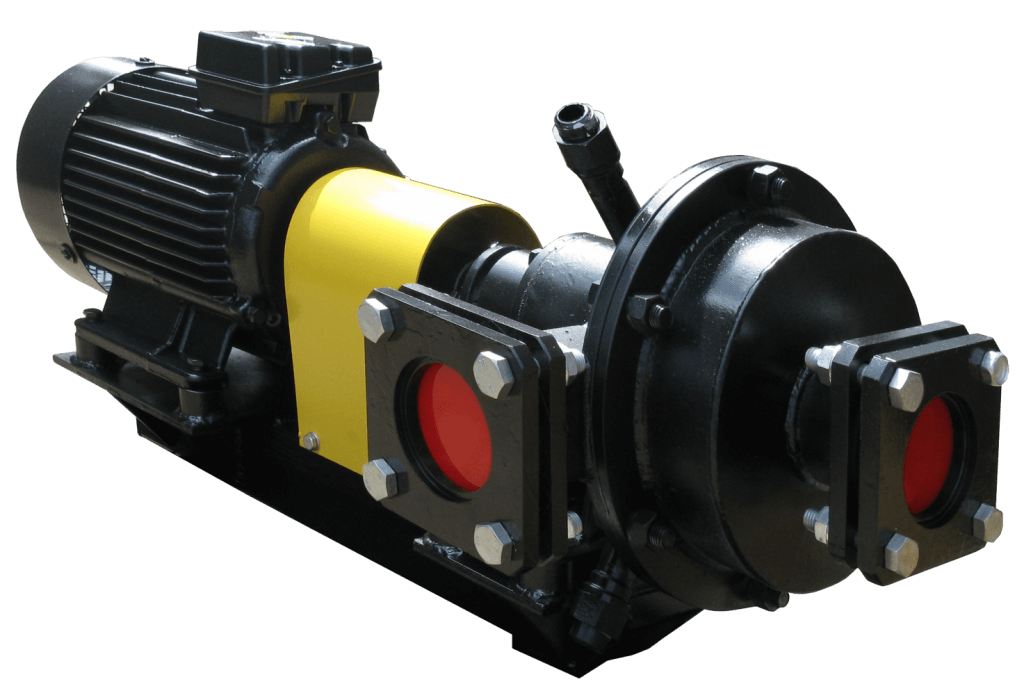

The UVB-1 bitumen emulsion units are semi-automated plants with components mounted on metal frame and connected with pipelines.

The rate of emulsion consumption depends on the type of surface treated. For asphalt surface, the consumption is 500 g/m2, in case of gravel the consumption grows to 1200 g/m2. Treatment of asphalt crumbs increases consumption up to 2000 g/m2.

Water-bitumen emulsion is a dark brown liquid. Emulsion is made by dispersing of bitumen in water with the addition of surfactants.

Bitumen emulsions are indispensible for various road construction tasks. It forms a protective layer for automobile roads (asphalt, gravel or concrete).

Specific areas of application are:

- creation of tack coat for road construction;

- permeation and surface treatment in road cover construction;

- creation of thin film wear layers;

- patch repairs (as part of mineral-emulsion mix).

Bitumen emulsions. General information. Principles.

The main component of any such system is the binding. In normal conditions, bitumen is solid, therefore to mix it with mineral material, it must be made liquid by heating.

An alternative – emulsification of bitumen

The amount of solid material (bitumen) in emulsion is up to 70%. In the form of small particles it is suspended in water. General viscosity of the emulsion coincides with the viscosity of water phase; therefore it is liquid at room temperature.

Emulsion stabilized by emulsifiers.

An emulsifier molecule is bipolar. The “tail” of the molecule solves in the bitumen particles, while the “head” pushed away other emulsifier molecules and does not allow bitumen particles to coalesce. This is why the particles remain suspended in water (emulsion stability). When emulsion contacts mineral material, the system balance is disrupted because emulsifier leaves the surface of bitumen droplets and the destabilized emulsion envelops gravel. The difference of chanrges between the grave and the emulsifier pushes out the water which then evaporates. Bitumen road emulsion is used as a binding film creating material in repairs and construction of automobile roads, bridges, streets, overpasses and other structures. The technologies based on pouring of material (surface treatment, tack coat, patch repairs and permeation) use fast setting emulsion. It can be used in all moderate to warm climates from Europe to Asia.

Quality – the ability to ensure high quality without the need to heat mineral material and binding. This alone saves up to 40% energy in comparison with regular “hot” process.

Environmental considerations. Bitumen emulsion does not cause harmful emissions in the atmosphere, there is no risk of explosion or burns during transportation or bitumen solution processing.

Transportation of bitumen emulsion

Bitumen emulsions are transported in special tanks, bitumen carrier, cubic vessels and metal barrels.

Storage of bitumen emulsion

Bitumen emulsions are stored in special tanks or other cylindrical vessels. The vessels must be clean: must not contain residual emulsions, bitumen, POL or other acidic or alkaline materials.

Emulsion of different composition must not be mixed in one vessel. Tanks must be tightly closed to prevent ingress of foreign objects and evaporation of water. The temperature of storage must be at least 5°С. If the volume of the emulsion is more than 1m3, the tanks should be equipped with special stirring agitators.

Our company offers special vertical emulsion storage tanks SBE and SMB to store emulsion and polymer modified bitumen respectively. These tanks are equipped with heating and circulation systems and can easily integrate into the existing production process of a facility.