Asphalt emulsions have been in existence for almost 100 years in the United States and the rest of the world. They were first developed in the early 1900s, used in road applications in the 1920s, with continued growth due to World War II and the energy crisis of the 1970s (1).

Asphalt emulsions have found their way into every road building application from sealing surfaces, to bonding layers of pavement, to mixes for road bases and surfaces. The test methods for their identification, handling, application, and quality control have advanced as the industry has embraced their many uses. This paper gives an introduction to these test methods based on four categories: plant quality control, shipping and storage, application, and identification. A brief look at the future evolution of the testing of emulsified asphalt products will be given to summarize this paper.

PLANT QUALITY CONTROL

For a plant to manufacture a good quality emulsion for a specific application in industry, a good testing protocol must be established for the components going into the product as well as the manufacturing process. Whether an emulsion is cationic, anionic or nonionic, a solution must be made prior to milling the emulsion. This solution is made by adding water in a tank at the appropriate temperature for blending or reacting an emulsifier. The order of addition of emulsifiers, additives, acids, or bases is critical to the consistency of manufacture.

The proper massing, or volume measurements, of the components is the first critical step to a quality production process. Once the components are in solution, the pH of the solution should be checked to ensure it is within the requirements for production. If the solution meets the pH requirements, the asphalt emulsion can be prepared by running the solution and asphalt through a milling process. The milling process includes blending the proper amount of asphalt into the solution, which must be monitored by emulsion residue or water content. The emulsion residue is quickly checked during the milling process by the heated evaporation of water from the emulsion, usually using a hot plate. Depending on the application for the emulsion, the water component in the emulsion can be 30%–45% of the product. After the run of emulsion is complete, a distillation residue is usually completed on the tank to verify the production values.

SHIPPING AND STORAGE

Once the asphalt emulsion has been manufactured for an application, tests must be conducted on the material to ensure it has the appropriate stability for storage and shipping. The weight of asphalt is very close to that of water, which helps in the ability of the asphalt to not settle to the bottom or cream to the top of the final product. Tests such as settlement and storage stability are done at 24 h and 5 days after manufacture to ensure the product maintains a good consistency.

The tests involve taking samples for residue testing from the top and bottom of a cylinder after the specified time has elapsed. The differences in residue properties from the top to the bottom are compared to make sure they are within specifications for the application.

The temperatures at which the emulsions are shipped for various applications can also be important. Some emulsions may need to be cooled prior to shipping, while others need to have their temperature maintained at those close to the temperature at manufacture.

Although there are no pump stability tests currently specified by agencies, many asphalt emulsion manufacturers incorporate internal procedures to verify that the final product will maintain stability during the pumping that is required between tanks and on the machines that are used for application. These tests usually require cycling the emulsion through positive displacement (usually gear type) pumps and checking for material that may break out during pumping.

APPLICATION

Asphalt emulsions are used for various applications in the road building industry. The main properties that are required from the emulsion are the ability to coat aggregates during the mixing process, form a uniform film for sealing or bonding layers, and enough stability for the application.

Emulsion viscosity is a main test for the application of products. In a mixing application of dense graded aggregates, a thinner viscosity of emulsion is usually required. For an opengraded application, a thicker emulsion is usually desired to get the appropriate film thickness. An asphalt emulsion used for bonding layers of asphalt needs to be thin enough to make a uniform layer and may need to be diluted with water to achieve the desired properties. For seal coating with aggregate chips, the emulsion needs to be thick enough to form the appropriate layer of emulsion for the size of chip while not forming drill marks or running off the road. Over a period of time, the asphalt emulsion that is manufactured at the plant may have its particles grow in size due to many different effects. The sieve test for asphalt emulsion can verify that the emulsion has not deteriorated to a degree that would interfere with passing through spray nozzles or possibly even cause a pump stability issue. A particle size analyzer can also be used to test the degree of homogeneity.

IDENTIFICATION

Since asphalt emulsions are used for many different applications, there are test methods to classify emulsions by charge as well as speed of setting (slow, medium, or rapid) to determine the appropriateness for specific uses.

A particle charge test is done to verify whether an emulsion is cationic. This can be important if mixing with certain aggregate mineralologies. Some aggregates will mix better with anionic or nonionic types of emulsions, while others perform better with cationic materials.

Demulsibility and breaking index tests can be done to verify a proper break for many seal coating applications. The demulsibility test takes a known salt solution and mixes it with an emulsion to cause the emulsion to chemically break. The amount of this break can be used to determine the rapid setting nature of the emulsion. A breaking index test can also be performed that uses a silica flour to blend into an emulsion. The break that occurs in this test is usually more of a surface area effect than a chemical break.

Together these tests can be useful tools to verify a rapid setting emulsion. The cement mix test is an important test for cold mix applications. A Type III high early strength portland cement is blended with an emulsion at a specified ratio to ensure that the emulsion is stable for the mixing process. Although this is a useful test, the stability of the actual components to be used in the field should be verified through coating tests with the aggregates and emulsions to be used.

Some emulsions require the addition of solvents such as naphtha, kerosene or diesel fuels to perform appropriately. An oil-in-distillate value from the distillation process can be used to verify the amounts of these materials in the emulsion. Distillation temperatures can vary from 135ºC to 260ºC. The oil distillate is measured as a layer of oil on the water recovered from this process in a graduated cylinder.

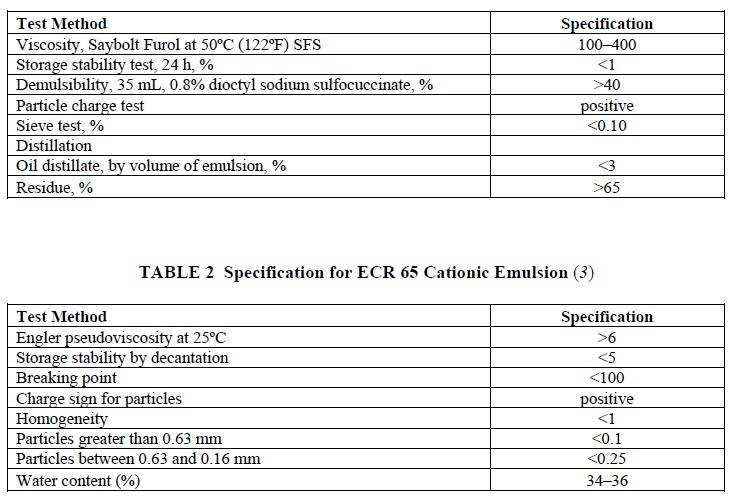

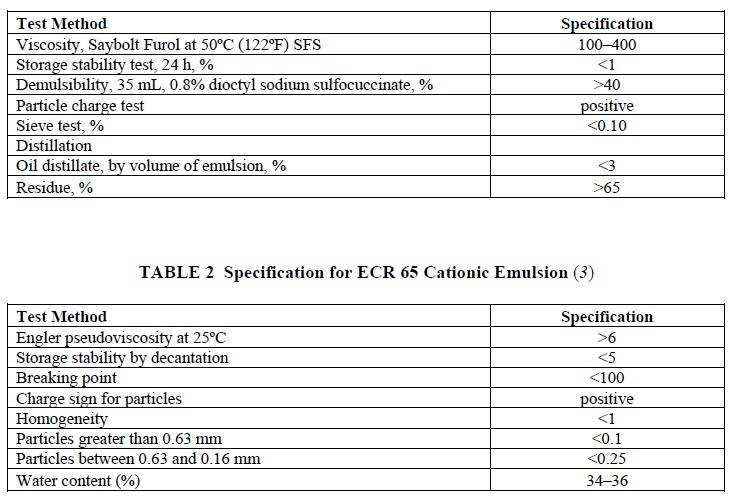

Table 1 and Table 2 show emulsion tests used to specify a comparable rapid setting type of emulsion that is used in the United States and Europe.

TABLE 1 Specification for CRS-2 Cationic Emulsified Asphalt (2)

WHAT IS NEEDED FOR THE FUTURE?

Many of the tests described above have been in the asphalt emulsion industry for years and have been effective for producing and applying the products. There are areas for improvement that the industry has determined, however, which will advance the use and consistency of the asphalt emulsion products.

Probably the greatest need that exists is the method of recovering a residue that is appropriate for field applications of the materials. The distillation methods used are completed at temperatures that are well above those that the product is exposed to in the field. Even with vacuum procedures to bring the temperature down, the question remains as to the true values one can achieve on the residue as compared to that which is seen in the field. With the use of polymer modified asphalts or latex additions to the emulsions, there is even a greater concern to recover the appropriate material representative of what is applied in the field. Recent efforts that have used evaporative techniques on thin films at 25-60ºC have produced encouraging results.

Improved ways of measuring asphalt emulsion viscosity are also being evaluated. The great concern is the consistency of values achieved comparing those of a Saybolt type of viscometer to a paddle wheel or rotational spindle viscometers. Viscosity measurements at field application temperatures are also important to better define the performance.

There are also improvements that can be made in the identification tests. Testing that includes the actual materials being used to mix or seal coat in the field should be considered.

Testing that would tie together the asphalt emulsion products with their final application for performance should be the ultimate goal.

REFERENCES

1. A Basic Asphalt Emulsion Manual. MS No. 19, 3rd Ed., Asphalt Emulsion Manufacturers Association and Asphalt Institute.

2. Road and Paving Materials: Vehicle–Pavement Systems, Vol. 4.03. ASTM International, revision issued annually.

3. Bitumen Emulsions: General Information and Applications. Syndicat des Fabricants d’Emulsions Routieres de Bitume (SFERB), 1991.

ARLIS KADRMAS