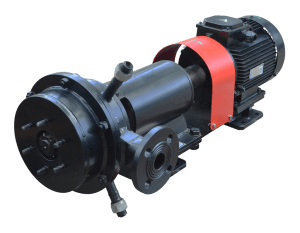

Colloid Mill for peanut butter

The universally known peanut butter (also known as peanut paste) was invented in 1890. However, its production was a demanding and physically challenging process. With time many devices to reduce human workload have been invented. GlobeCore produces a mill, which significantly simplifies processing of nuts into paste. The mill is suitable for production of emulsion and other processes, such as homogenization, emulsification, dispersion, mixing etc.

The mills for the food production industry are made from food grade stainless steel. On the average, the time between placing the order and shipping the device to the client is 45 business days. The equipment is not our stock product, and is manufactured according the client’s specification. Custom orders are manufacture in 45 to 60 business days.

The device is ready for operation immediately after installation into the production line, but it can also be used as a stand-alone application.

СLM – 22 Homogeniser mixer, emulsifying machine

If you are interested in our offer, you are probably:

- Company owner or general manager, interested in quality production and fast sales of your products, since food products are perishable.

- Process engineer, developing recipe and observing compliance. You understand that wet grinding homogeniser will optimize production and technology.

- Working in material department, and your main objective is to find the correct equipment required by your company in the market of equipment and services. Your most important task is to make the process and production departments’ operation optimal.

You are on the right track!…

In just a few steps you can obtain the essential helper for your “kitchen”:

- Fill out the questionnaire.

- Call us and we will review your questionnaire together.

- Will will suggest options and prices, and will inform you of the lead time.

- If possible, we will also meet at our factory.

- We will ship and commission the device on your site.

Is it true that …

A colloid mill cannot mix and pulverize at the same time? (For instance, to prepare peanut butter, to pulverize peanuts and homogeneously distribute it in the product).

It can. Dispersion will be down to 1 micron. The end product is liquid and homogenic.

The main advantages of the wet grinding GlobeCore emulsifying machines are:

- Modern design and high quality of the device

- Competitive price

- Competent engineering consulting

- Fast production of the order

- The efficiency and speed of mixing at times more than a turbine agitator

- Savings on storage capacity compared with a turbine agitator – emulsifying machine is built into a production line and does not require additional tanks

- Stability of the mix to stratification

- Heating/cooling jacket

- High-tech production lines and qualified staff (over 200) allows to expedite orders

- Ability to adjust the gap of the grinding zone without the need to remove the device from the production line

- Grinding to 1 micron

- Component parts from universally recognized manufacturers

- Operating temperature range from -30 С° to 180 С°

- Optional soundproofing

To upgrade and optimize your production by commissioning a GlobeCore emulsion machine, we suggest you fill out a questionnaire, so that a manager may suggest a specific model of equipment. The next step is placing the purchase order. From there, our company will manufacture the specific mill. After the mill is produced, it will be tested at the manufacturer’s test site and will be shipped to the client. We can also assist with installation and commissioning of the mill on your location.

The СLM colloid mill is specifically designed for production of highly stable colloidal solutions, superfine suspensions, blends and emulsions. The mill features wet grinding due to the gap between rotor and stator cones.

The centrifugal force and high velocity of the rotor relative to the stator cause the liquid and semi-liquid materials to become homogenic and disperse finely. The mix of any materials becomes a finely dispersed homogeneous emulsion.

Besides, the device features cavitation effect: caverns explode under internal pressure.

The degree of dispersion and pumping qualities may vary according to mechanical properties of the ground material and carrier phase.

| No | PARAMETER | CLM – 22.2 | CLM – 18.1 | CLM – 4.1 | CLM – 05.3 |

| 1 | ***Capacity rated, m³/hour, up to. | 22 | 18 | 4 | 1,8 |

| 2 | Operating pressure, bar. | 0,5 | 0,5 | 0,5 | 0,5 |

| 3 | Rotation speed, RPM | 3 000 | 3 000 | 3 000 | 3 000 |

| 4 | **Max heat carrier temperature, °C | 160 | 160 | 160 | 160 |

| 5 | **Minimum coolant temperature, °C | -4 | -4 | -4 | -4 |

| 6 | Dispersion, micron | <50 | <50 | <50 | <50 |

| 7 | Nominal pressure/suction bore diameter, mm | 80/120 | 80/80 | 32/65 | 32/32 |

| 8 | Drive power, kW | 55 | 11 | 5,5 | 3 |

| 9 | *Dimensions, mm- length

– width – height |

1440

430 650 |

1000

400 460 |

960

310 400 |

960

310 400 |

| 10 | Weight, kg | 490 | 135 | 125 | 125 |

Note.

* – Dimensions are driven assembly.

** – If necessary, the product can be either heated or cooled to a desired temperature.

*** – Depending on the physical and chemical characteristics of the product capacity may vary.

Feedback of GlobeCore’s customers

Mr. Shekanabo, the United Republic of Tanzania:

“I can only say good things about GlobeCore mills. After seeing the production facility, I had no doubts that this is a serious and reliable company with professional staff, and the system works like a clock. Of course, the production itself seems complicated, but the equipment is powerful and rugged.”

Our location:

The production facility is located in Oldenburg-Eversten, Germany, Edewechter Landstraße 173.

For making an order fill the questionnaire or call us.

Skype: mezhievskiy