Petroleum industry

Emulsification pump for Petroleum industry

Colloid mill GlobeCore is not only mill, but also the pump with 2 bar on output.

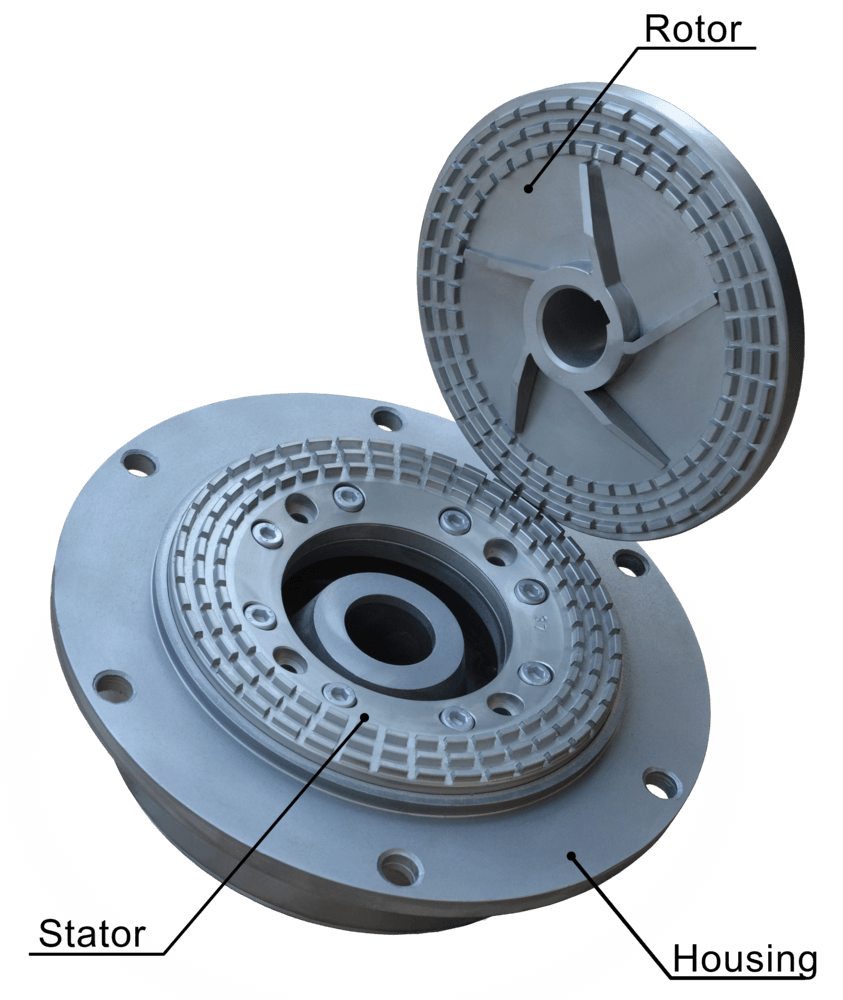

The main principle of grinding in the colloid mills is wet grinding. This technique is based on feeding pre-mixed solid and liquid insoluble components of suspension or emulsion into the grinding zone of the mill, which consists of the following components:

After the product enters the grinding zone, the process of homogenization and dispersion begins: one substance (solid) is pulverized and is evenly dispersed within the other substance (liquid phase), creating a stable homogeneous emulsified product. The fine degree of grinding in the GlobeCore mills is facilitated by proprietary design of the cutting parts of the mill and may reach 1–5 micron. The impeller of the rotor also creates cavitation effect, which further accelerates the dispersion process.