Types of dispersants

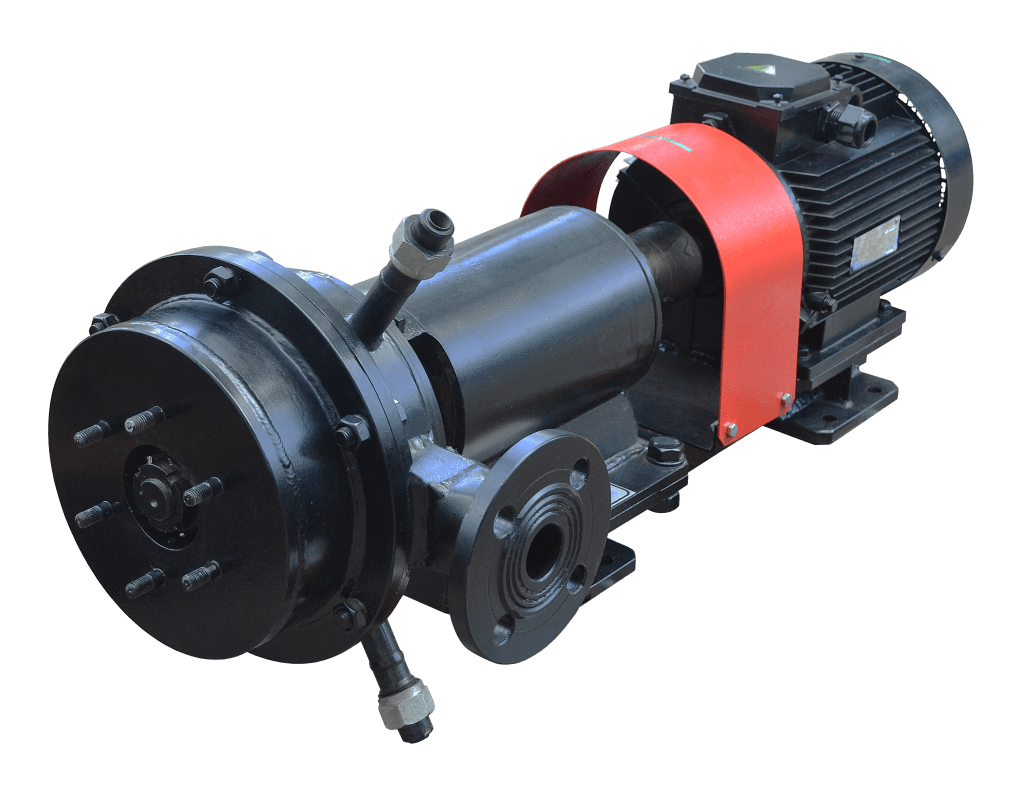

GlobeCore manufactures and sells dispersers and homogenizers for production of highly stable colloid solutions and other dispersed systems (poweders, suspensions and emulsions).

There are several types of dispersers: caviation, rotor-stator and high pressure dispersers. The most efficitent of these are the colloid mills, which can both disperse and homogenize material based on the principle of “wet” grinding. Such equipment has several advantages: high production capacity and homogenation, a heating jacket, preparation of highly stable emulsions and superfine colloid suspensions, the use of cavitation and shear effects. Colloid mills are widely used in production of food, paints and construction works, as well as farmaceutical and cosmetic industries.

Dispersers can also be divided into submerged and inline. Submerged dispersers homogenize and disperse liquid and viscous mateirals, as well as production of water-emulsion paints. The unit resembles an agitator and is mostly used in laboratories, but some models are used in industrial applications as well.

An inline disperser is designed for homogenation in line or for recirculation of a material. The most widely used inline dispersers are ultrasonic stream dispersers and high pressure dispersers.

Ultrasonic inline dispersers are used for multiple cavitation treatment of material in liquid dispersed media in the process of stream dispersion. The process occurs in a high intensity ultrasonic field, created in the resonance chamber.

High pressure dispersion is an energy saving devices, designed for fragmentation of particles to the nanometric range and preparation of super-fine emulsions, since increased pressure improves fragmentation.

Dispersers of oil and derivaties are used in oil processing. Cavitational processing of oil at the stage of preparation and transportation is rather demanded. Dispersal lowers viscosity of material and decreases settling temperature.

At present the emulsion of water and heavy oil is becoming more and more popular. This emulsion has several advantages in terms of transportation and handling as well as combustion, imroves performance and environmental safety. The device also ensures production of highly stable fine water-oil emulsion by cabvitation treatment of material with subsequent emulsification