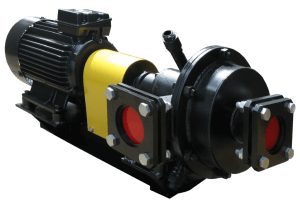

Hydrodynamic devices: emulsifier pump and disperser pump

GlobeCore offers state of the art colloid systems designed for preparation of highly stable dispersion systems, superfine suspensions and emulsions applying wet grinding principle.

Dispersion systems are stable materials formed of two or more substances which do not normally mix or react chemically. Such systems include powders, suspensions, colloid solutions and emulsions. Dispersion systems are created by dispersion and homogenization of one material in another into a uniform stable system, where one material (dispersion phase) is atomized in the other (dispersion medium). Such processes occur in special devices: homogenizers, dispersers and colloid mills.

There are several ways of raw material processing, one of which is the hydrodynamic method. Hydrodynamic processing is performed by hydrodynamic dispersers, homogenizers and emulsifier pumps. Emulsification of the material during hydrodynamic treatment is made due to cavitation, which occurs in alternating pressure area. Pressure drop during hydrodynamic cavitation occurs due to acceleration of liquid flow. Another significant factor is the interaction of shockwaves and collisions of solid particles of the solid dispersion phase.

Emulsifier pumps are hydraulic devices designed for production of stable dispersion systems by atomization and mixing of material by the flow of liquid. Emulsifier pumps convert the physical energy of the drive motor to the kinetic energy of liquid. Such dispersion devices as emulsifier pumps are perfect for preparation of highly dispersed oil systems, emulsions, mixing and pumping of paints.

A disperser pump, which allows to simultaneously disperse, pump and mix the raw material, is widely used in hydraulic systems. This invention increases reliability and durability of mixes with varying viscosity.