Blending systems

The blending system USB is designed for inline mixing of two to five liquid components. The unit can be used for production of multicomponent motor fuels, including those with vegetable additives, bioethanol, biodiesel with diesel fuel.

The regular blending methods cannot prevent separation of the blend of several different components. The advantage of the USB blending system is that the injection and the hydrodynamic shock guarantee a stable blend up to 180 days.

The modern hydrodynamic (inline) blending systems have proven to be economical, precise and stable in production of high quality mixes and optimization of costs. The savings and increased production efficiency as compared to the traditional tank mixing can reduce return on investment time by 60%, so that the project pays for itself within one year or less.

A USB blending system is designed individually for each customer to provide optimal equipment for the required task.

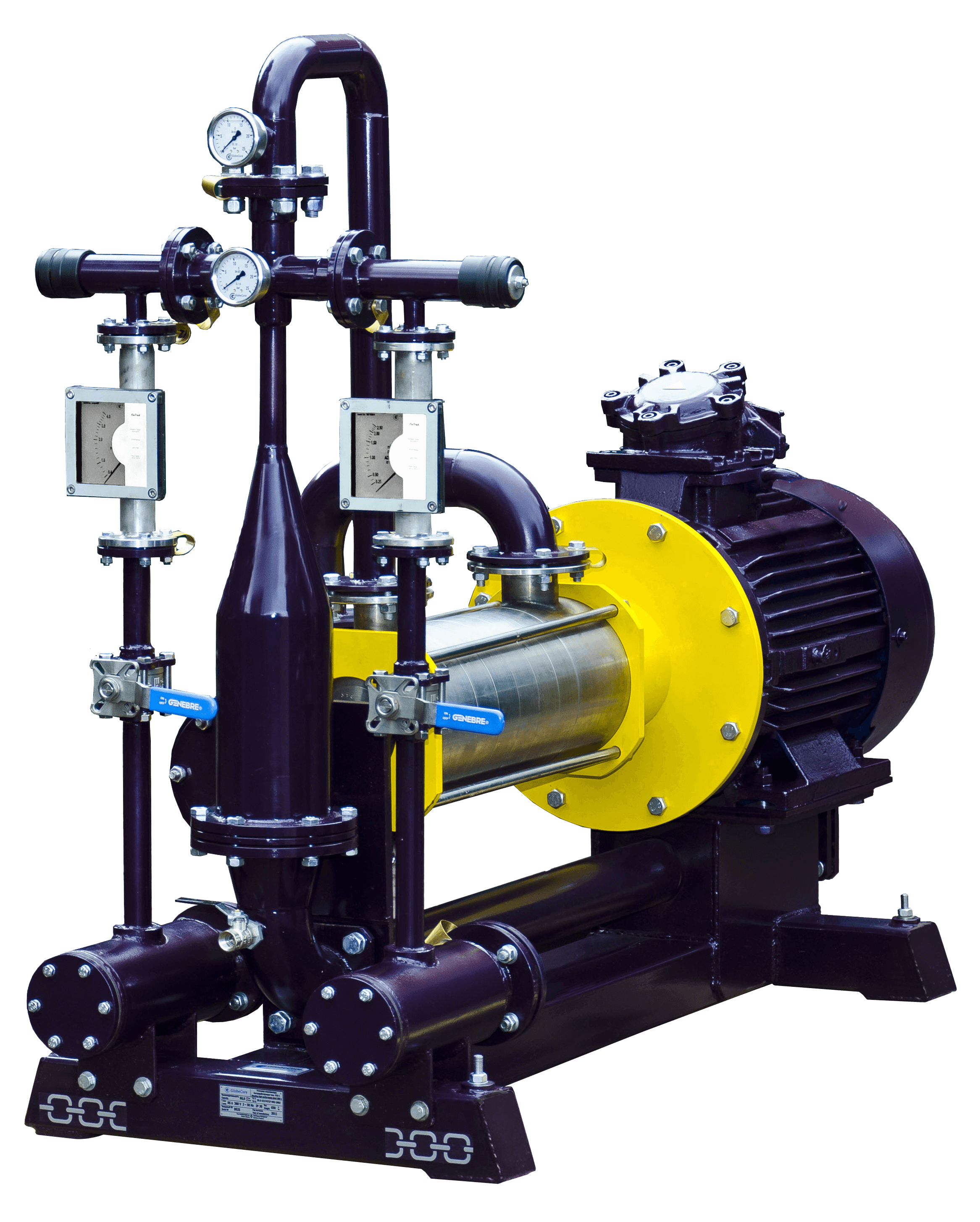

HYDRODYNAMIC MIXER

The hydrodynamic mixer utilizes a process, which allows injecting all components simultaneously in predetermined ratio into a common blending manifold, which then supplies the finished product to storage tank. The advantages of this technology is precise control of component portioning, drastic reduction of blending cycle time and elimination of blending tanks for homogenization of the blended product. Flow rate of each component in the inline blending system is constantly adjusted to provide stable quality product as required by the recipe at unit outlet.

Your product manager at GlobeCore:

Sergey Mezhievskiy

A responsible and dedicated person. He will accompany you through all stages from placing the order to shipment of the product. Experience in industrial sales and in finding solutions for real issues in the field allows him to fully understand you, select the appropriate equipment model and ensure timely delivery.

Skype: mezhievskiy