A question that is often asked: why do we need a disperser, when we already have a mixer? First, let’s look at the definitions. A mixer is a device that is generally used in cooking for mixing food products. In fact, a mixer simply mixes the components in a container. As for a disperser, it grinds the raw material, producing a homogeneous mixture.

Theoretically, it is possible to produce emulsions (suspensions) with a mixer, but because the large particles will still be present, the emulsion will not be stable, and in the course of time it will break.

There is another appliance that is similar in purpose – a homogenizer. It mixes solid and liquid components to obtain mixtures of uniform consistency. Homogenization, partially include dispersing, but rather as an additional effect, and not the main process. Functionally, a homogenizer is a mixer for industrial use.

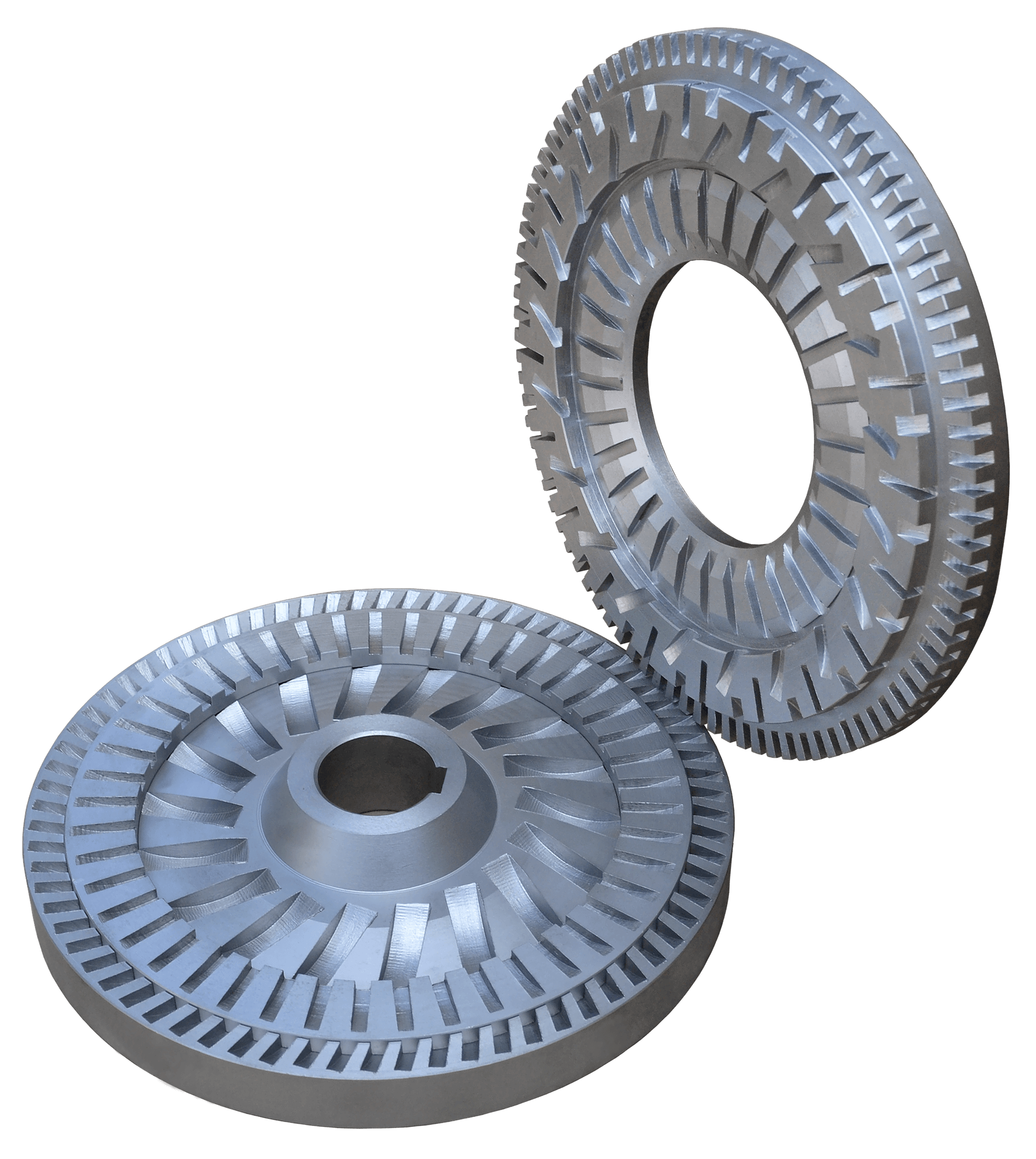

GlobeCore advises you not to puzzle over what you need more: a homogenizer or a disperser, and choose a universal option. Colloid mill KLM is at the same time a homogenizer and a disperser. This unit obtains highly stable colloidal solutions, ultrathin suspensions, mixtures and emulsions with particle size 1 μm. This result is provided by a number of factors that occur in a colloid mill:

- centrifugal forces;

- high relative speed between rotor and stator;

- grinding;

- cavitation;

- increased turbulence, etc.

GlobeCore colloid mills can easily integrate into existing production lines to increase their efficiency. The components are fed into the mill at a certain ratio of solid and liquid phases to provide a constant productivity.