Water-bitumen emulsion is highly appreciated by building and road construction companies. This is due to its ease and safety of use in comparison with the mixtures based on solvents of and from petroleum products such as kerosene. As a rule, water-bitumen emulsion is obtained by blending liquid bitumen with water and special emulsifiers and acids.

Having years of experience in designing and building blending machines and bitumen emulsion units, GlоbeCоre is one of the most reliable manufacturers of modern equipment for production of water-bitumen emulsions anywhere in the wolrd today.

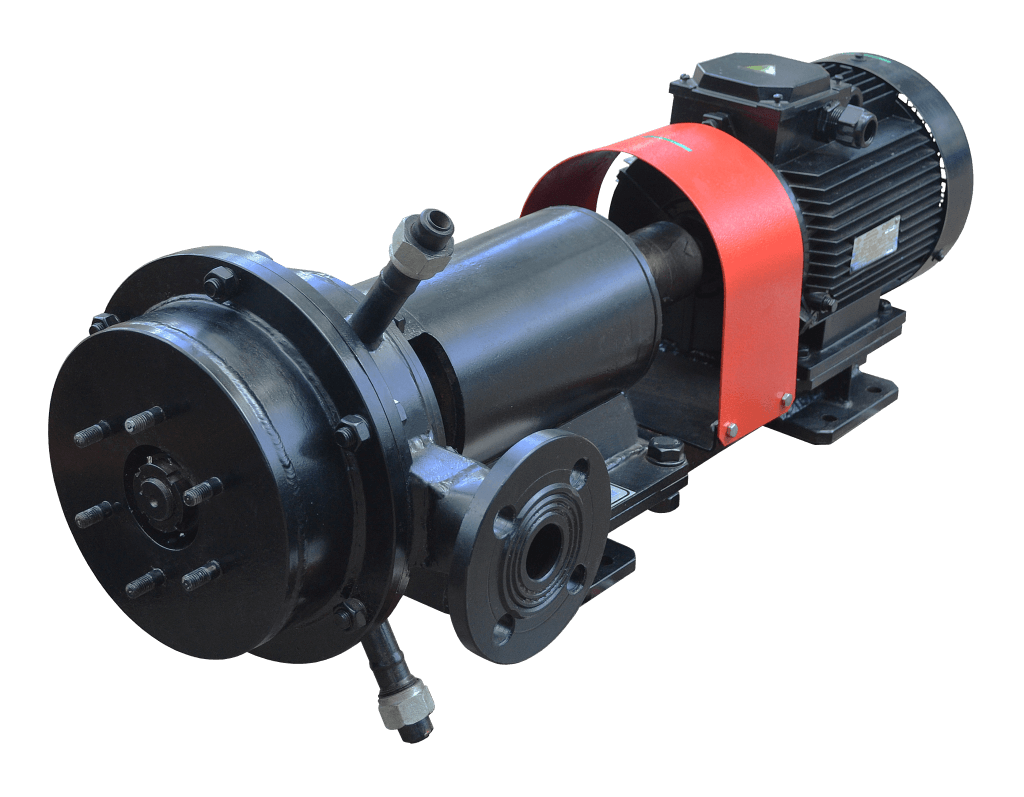

A colloid mill is considered to be the heart of any bitumen emulsion production equipment where bitumen is grinded into small droplets and is then evenly distributed in water. In the past, manufacturers of equipment used blending equipment such as dispergators and ultrasonic homogenise that perform the wet grinding of the dispersed phase of bitumen production.

GlоbeCоre Colloid mills for wet grinding can produce highly-stable dispersed systems from two or more mutually insoluble substances. Bitumen emulsion units (depending on the desired size of bitumen droplets) use three groups of colloid mills.

The first group of colloid mills provides 90% of droplets with a size of less than 5 microns (a minimum size of a droplet of 1-2 micron). They are used to manufacture polymer-modified emulsions, bitumen emulsions for surface treatment ( “chip seal”), recycling, soil stabilization, grouting, tack coating and similar technological processes.

The second group of colloid mills provides 90% of droplets at the outlet with the size of less than 10 microns (a minimum size of a droplet of 4-5 micron). The areas of its application include: simple slurry mixtures, surface treatment, tack coting, recycling, and grouting.

The third group of colloid mills produces bitumen emulsions with a minimal size of a droplet of more than 5 microns (no more than 10% of droplets are larger than 10 microns). Such bitumen emulsions are used for surface treatment, tack coating and grouting.

Since colloid mills are mostly mounted in line with continuous blending units, components are supplied directly to the unit. As a rule, the water phase is prepared in advance to withstand the required temperature, PH level and emulsifier metering. Then the water phase and warmed-up bitumen are supplied to the input of the colloid mill to be dispersed. If necessary, the viscosity of bitumen is reduced by injecting flux to the feed line.

The ratio of components is maintained automatically by metering pumps in accordance with the program or by temperature control of the source components, by measuring the temperature of bitumen emulsion at the outlet (as a rule it is 85-94°С) and the subsequent flow adjustment.

If required (depending on the formula), the colloid mill may be supplied with latex that allows for modified bitumen emulsion production. At the outlet of a colloid mill, there is a three-way valve that provides recycling of water solution of emulsifier, mill flushing or discharge of the finished bitumen emulsion product.

GlobeCore‘s continuous bitumen emulsion equipment has a wide range of benefits that include; (1) a rapid change of the type of emulsion produced; (2) no impact of reagents on the staff; and (3) low operating costs.