Evolution of the mill: from grain bruisers to colloid systems

The history of the mill begins in prehistoric times and the mechanism itself is one of the oldest inventions ever. The mill is a device for grinding carious materials. Predecessors of the mill are the grain bruiser and mortar and mallet, but as husbandry developed, a need arouse for a more efficient way of grinding. Therefore, original hand driven grindstones were followed by heavier millstones, driven by human and, later, animal power.

As technology progressed, the energy of running water was harnessed; the water drive operated as an automatic pump driven by a stream of water from a running spring. It was flour milling where first water mills not requiring muscle power were first invented. By combining the idea of water driven mill with the sail, i.e. using wind energy, the first windmill was invented in the ancient times, and became the chief symbol of a peasant’s prosperity.

Even with all the technological progress, millstones are still in used by some peoples: there is a lot of lore related to millstones and mills in general.

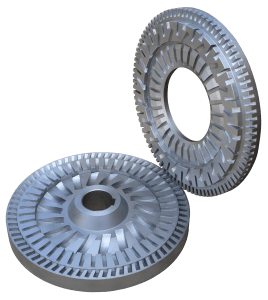

A significant breakthrough in the industry was acheved with the advent of breakers and crushers, which pelletized materials mechanically. The modern crushers are divided by fragmentation size, design, method of installation and purpose. There are five main types of crushing machines: cone crushers, swing hammer shredders, jaw crushers, roll crushers and disk mills. Rotary mills and ball mills are also crushers for fine fragmentation of dry material.

Dry grinding allows to use large fragments of source material, since the impact of the balls is more efficient than the “wet” grinding. At the same time, the “wet” grinding mills are the most efficient way of colloid solution preparation.

At present, there are some inventions for nano-grinding of liquids. These include dispersers, colloid mills, ultrasonic homogenizers and cavitators. These technologies offer superfine fragmentation of organic and non-organic material in the nanometer range. The products of these mills show high stability, strength and viscosity performance. These devices produce a highly dispersed system, a colloid solution of two or more insoluble and mutually chemically inert substances.

GlobeCore manufactures high quality devices (colloid mills, dispersers, homogenizers and blenders) for production of highly stable dispersed systems.

The main area of expertise of GlobeCore is the production of the UVB units which produce water-bitumen emulsions.