Advantages and variations of a cavitation disperser

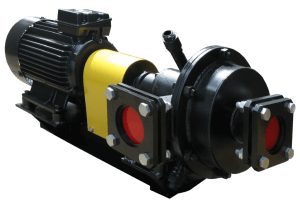

GlobeCore manufactures high quality disperser systems for production of stable dispersion systems: emulsions and suspensions.

Despite the fact that the colloid mill is the most efficient system for dispersion and homogenization of raw material, any grinding machine is based on a disperser. The process of dispersion is the process of atomization of solid and emulsification of liquid materials with subsequent mixing into a stable and homogeneous dispersion system of two or more materials, which normally do not mix and do not react chemically. Dispersers are actively used by the food industry, in paint production, in construction, as well as pharmaceutical and cosmetic industries.

Depending on the effect on the raw material, dispersers are divided into several types: cavitation, rotor-stator, and high pressure dispersers. The most wide spread disperser is the cavitation disperser, designed for dispersion of liquid or solid components after cavitational treatment. The process of cavitation involves formation of steam bubbles (caverns) in the flow of liquid due to sharp pressure drop below a certain critical level. There are two methods to create cavitation: hydraulic shock and ultrasonic impulses. Cavitation disperser may therefore be of the following types: hydrodynamic, ultrasonic (acoustic) and mixed-type, e.g. hydroaccoustic dispersers.

An ultrasonic cavitation disperser creates an ultrasonic field of high intensity in the resonance chamber. Any material in such disperser is subjected to multiple cavitation treatment by the passing acoustic waves.

The hydrodynamic cavitation disperser is quite economical, but not less efficient. Pressure drop for hydrodynamic cavitation occurs doe to acceleration of charged flow of liquid droplets. There are several types of hydrodynamic cavitators, of which the main modifications are DG-2, DG-40, DGS-40-20.

Cavitation dispersers enjoy certain advantages: economy of raw material and chemical agents, reduction of time and labor cost as well as high quality and stability of produced emulsions and solutions.