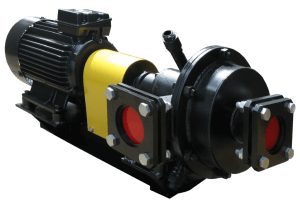

NGD type homogenizer pump

GlobeCore offers state of the art colloid systems designed for production of stable colloid solutions, superfine suspensions and emulsions using wet nano-grinding principle.

Dispersion systems are stable materials formed of two or more substances which do not normally mix or react chemically. Such systems include powders, suspensions, colloid solutions and emulsions. Dispersion systems are created by dispersion and homogenization of one material in another into a uniform stable system, where one material (dispersion phase) is atomized in the other (dispersion medium). Such processes occur in special devices: homogenizers, dispersers and colloid mills.

A homogenizer is a mechanical devices, designed for production of fine and uniform (homogeneous) stable material by atomization of raw material to micron dimensions. The device facilitates homogenization of insoluble materials and formation of mixes, suspensions and emulsions by elimination of microscopic irregularities. During homogenization, the dispersion phase is uniformly distributed. Homogeneity and viscosity of the product is established. Such devices are widely used in food industry for production of puree, pastes, sauces, condensed milk etc, and in cosmetic industry for production of salves, lotions and gels.

CLM – 4 Homogeniser

Preparation of food mixes and cosmetics is done by passing the material through the head of homogenizer pump and its super-fine atomization and mixing. The NGD homogenizers are approved for use in food production. Homogenizer is also used for production of process mixes and chemical materials.

Homogenizer pump (NGD) is a hydrodynamic device of pulse-rotor type. This devices enjoys several benefits and is quite simple for assembly, installation and operation. The main components of the pump are the homogenization head with a single seal, a bearing assembly and an electric motor.