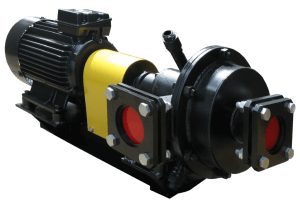

Inline homogenizer

All over the world, a great many of chemical companies are involved in mixing (emulsification, dispersion and homogenization) of mutually insoluble substances: dispersion phase and dispersion medium.

Dispersion phase is a component which is evenly distributed across the second component, the dispersion medium, and the emulsion is stable for a duration of time. These processes run quite well in a colloid mill. The next question is whether the mill can be operated alone or in the production line?

GlobeCore colloid mills can be operated either as a standalone application or retrofitted into the existing production lines. Operating pressure of a high speed emulsifying machine in a production line varies from 1.5 to 2.5 bar, depending on chemical and physical properties of the product.

The main advantages of the wet grinding GlobeCore colloid mills are:

- Modern design and high quality of the device

- Competitive price

- Competent engineering consulting

- Fast production of the order

- The efficiency and speed of mixing at times more than a turbine agitator

- Savings on storage capacity compared with a turbine agitator – colloid mill built into a production line and does not require additional tanks

- Stability of the mix to stratification

- Heating/cooling jacket

- High-tech production lines and qualified staff (over 200) allows to expedite orders

- Ability to adjust the gap of the grinding zone without the need to remove the device from the production line

- Grinding to 1 micron

- Component parts from universally recognized manufacturers

- Operating temperature range from -30 С° to 180 С°

- Optional soundproofing

CLM – 18 colloid mill

CLM – 22 colloid mill

The product in the mill is ground between the rotating and stationary calibrated cylindrical radially skewed teeth of the rotor and stator.

The centrifugal force and high velocity of the rotor relative to the fixed stator cause liquid and semi-liquid materials to become homogenic and finely dispersed.

The mill simultaneously disperses and homogenizes materials.

A heat jacket allows to apply or dissipate heat to or from the grinding zone.

The mill features high performance capacity, allows to produce highly stable emulsions, as well as colloidal suspensions, ensures high degree of homogenization and particle size to 1 micron.

Processes are intensified by 100 – 600%.

Besides, the device creates cavitation, i.e. explosion of caverns by internal pressure.

The mill can be retrofitted into existing production lines.

For high quality grinding the product must enter the mill in certain proportions at constant rate.

The degree of granulation and pumping qualities may vary depending on the mechanical properties of the material and the carrier phase.

| № | Parameter | CLM – 4.1 |

| 1 | ***Capacity rated (on the water), m3/hour, up to. | 4 |

| 2 | Operating pressure, bar. | 0,5 |

| 3 | Rotation speed, RPM. | 3000 |

| 4 | **Max heat carrier temperature, °С. | 160 |

| 5 | **Minimum coolant temperature, °С. | -4 |

| 6 | Dispersion, microns. | <50 |

| 7 | Nominal pressure/suction bore diameter, mm. | 32/65 |

| 8 | Drive power, kW. | 5,5 |

| 9 | *Dimensions, mm:

– length – width – height |

960 310 400 |

| 10 | Weight, kg. | 125 |

Note.

* – Dimensions are driven assembly.

** – If necessary, the product can be either heated or cooled to a desired temperature.

*** – Depending on the physical and chemical characteristics of the product capacity may vary.

Notice:

GlobeCore is colloid mill manufacturer in Germany. Plant has its subsidiaries and dealer network allover the world. The equipment for bitumen emulsion blending is in compliance with all relevant international standards. All products certified accordingly. Quality control complies with ISO 9001:2001. Certificate No UA.2.039.02021-06.

Feedback of GlobeCore’s customers

|

Mr. Patel, the United Republic of Tanzania:

“I want to wish GlobeCore success in the future and I think we will maintain our cooperation for many more years. May you have as many successful products and new developments as possible.” |

|

Mr. Shekanabo, the United Republic of Tanzania: “I can only say good things about GlobeCore mills. After seeing the production facility, I had no doubts that this is a serious and reliable company with professional staff, and the system works like a clock. Of course, the production itself seems complicated, but the equipment is powerful and rugged.” |

Your product manager at GlobeCore:

Sergey Mezhievskiy

Sergey Mezhievskiy

A responsible and dedicated person. He will accompany you through all stages from placing the order to shipment of the product. Experience in industrial sales and in finding solutions for real issues in the field allows him to fully understand you, select the appropriate equipment model and ensure timely delivery.

Skype: mezhievskiy

Our location:

The production facility is located in Oldenburg-Eversten, Germany, Edewechter Landstraße 173.

For making an order please fill the questionnaire or call us.