Liquid paint production colloid mill: dispersing and mixing paint components with the solvent base

This will be of interest to paint and varnish production facilities: a colloid mill for dispersion and mixing of paint components with high precision, so that the end product is a uniform emulsified mass.

Homogeneity and stability of the emulsion is very important in paint production: if the suspensions are of different weights, they will soon separate. This will cause the first brush strokes to be smooth and uniform, while the last ones, made with heavy sedimented fractions, will look somewhat like sandpaper.

GlobeCore colloid mills makes great paint dispersing, so will ensure that the paint does not spoil the painted surface.

Our equipment can be stock or custom designed. The stock models are available for purchase from the warehouse. Custom models are built within 45 work days.

GlobeCore manufacturing facilities are located in Oldenburg-Eversten, Germany.

It takes about a week to commission a mill. You will need several days to prepare permits, communications (220 or 380V electric power supply, component lead in pipelines) and operator work place. This time is usually enough to ship the device. Actual duration of commissioning varies, but can usually be completed in several days.

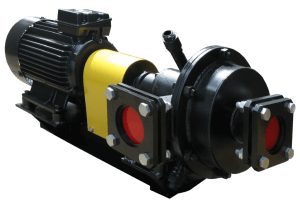

СLM – 18 colloid mill

Paint dispersing mixer СLM – 22

If you are reading this, you are probably:

-

The owner of a paint production company. You are not looking for expensive or economic solutions, instead, you go after effective ones, so that the investment brings you stable return instead of problems.

-

General manager of a paint company. You realize what to produce and what equipment to use, as well as where to purchase it, but maybe you keep putting it off. In the end, all you need to do is place that order.

-

Material department manager. You have to make the mangement happy by finding the best price and quality offer, creating and maintaining good working ties with suppliers. GlobeCore has built very good corporate and personal relations with our client over time.

-

Engineer, servicing the paint production lines. You want the machine to do three times the work and never fail. Do not hesitate to place the order. Sure, metal also fails, but we stand ready to support you with service, spare parts and out manufacturing facility.

Busting myths and assuaging doubts:

-

Can the mill be used for dry paint production?

Normally, no. The mill is meant for wet grinding, so, paint dispersing in liquid. -

Can the GlobeCore mill mix and grind and do dispersing at the same time?

Sure. Dispersion is as fine as 5 – 1 micron. The product must be liquid, which is just the thing for making dyes and paints from prepared powders. -

Will the emulsified product be stable after dispersing?

Yes. Our emulsions are very stable. You can send samples of your components to us along with the recipe to mix with the testbed machine.

Besides, we have many years of experience of adjusting and improving recipes for material obtained from different suppliers, which can be of great influence on final product quality. We can help you perfect the existing recipe or even develop a custom new recipe (which is quite a tedious process).

So, do you really need a colloid mill?:

- You need to mix mutually insoluble materials (homogenization), or uniformly disperse solid particles in a liquid (dispersion),

- The end product must be at least liquid or gel-like (to be able to flow through pipelines).

- You are looking for quality superior to Chinese products at the price lower than for the European equipment.

If the answer is Yes, we know how to help you. The GlobeCore colloid mill benefit your production!

What does it take to get the mill to start dispersing at your facility?

- Fill out the questionnaire

- Call us so that we can review the questionnaire together.

- We will advise on model, pricing and expected lead time.

- If possibility presents itself, we will meet at our facility.

- We produce and commission the unit on your location.

Advantages of GlobeCore colloid mills:

- Modern design and high quality of the device;

- Competitive price;

- Competent engineering consulting;

- Fast production of the order;

- The efficiency and speed of mixing at times more than a turbine agitator

- Savings on storage capacity compared with a turbine agitator – colloid mill built into a production line and does not require additional tanks

- Stability of the mix to stratification;

- Heating/cooling jacket;

- High-tech production lines and qualified staff (over 200) allows to expedite orders;

- Ability to adjust the gap of the grinding zone without the need to remove the device from the production line;

- Grinding to 1 micron;

- Component parts from universally recognized manufacturers;

- Operating temperature range from -30 С° to 180 С°;

- Optional soundproofing.

| No | PARAMETER | CLM – 22.2 | CLM – 18.1 | CLM – 4.1 | CLM – 05.3 |

| 1 | ***Capacity rated, m³/hour, up to. | 22 | 18 | 4 | 1,8 |

| 2 | Operating pressure, bar. | 0,5 | 0,5 | 0,5 | 0,5 |

| 3 | Rotation speed, RPM | 3 000 | 3 000 | 3 000 | 3 000 |

| 4 | **Max heat carrier temperature, °C | 160 | 160 | 160 | 160 |

| 5 | **Minimum coolant temperature, °C | -4 | -4 | -4 | -4 |

| 6 | Dispersion, micron | <50 | <50 | <50 | <50 |

| 7 | Nominal pressure/suction bore diameter, mm | 80/120 | 80/80 | 32/65 | 32/32 |

| 8 | Drive power, kW | 55 | 11 | 5,5 | 3 |

| 9 | *Dimensions, mm

– length – width – height |

1440 430 650 |

1000 400 460 |

960 310 400 |

960 310 400 |

| 10 | Weight, kg | 490 | 135 | 125 | 125 |

Note.

* – Dimensions are driven assembly.

** – If necessary, the product can be either heated or cooled to a desired temperature.

*** – Depending on the physical and chemical characteristics of the product capacity may vary.

Frequently asked questions:

- How much solid phase can the mill handle?

Solid phase for dispersing can only be added to the СLM-22 mill, up to 6%. - What kind of dispersion is expected after processing with the colloid mill?

Degree of dispersion and pumping characteristics may vary depending on physical and mechanical properties of the dispersed material and carrier phase. We will need to see the recipe to give a more specific answer.

The technology of the colloid mill allows for 5 – 1 micron dispersion. - What is the construction material?

Stock mill: cutting part is made from black steel AISI 304, 316. - What is the power consumption during dispersing?

The drive consumes: 45, 11 and 5.5 kW for СLM-22, СLM-18 and СLM-4 respectively. - What are the shipment options?

The mill ships worldwide after down payment. - What kind of lead time should be expected?

Usually from 30 to 45 business days. This may depend: for instance, if the required model is in stock at the warehouse. - What is the pressure at homogenizer outlet?

Around 2-3 bar.

Equipment ships worldwide.

Warranty – 12 months from commissioning.

Clients speak about GlobeCore mills:

Mr. Nshekanabo, United Republic of Tanzania:

Mr. Nshekanabo, United Republic of Tanzania:

I can only say good things about GlobeCore mills. After seeing the production facility, I had no doubts that this is a serious and reliable company with professional staff, and the system works like a clock. Of course, the production itself seems complicated, but the equipment is powerful and rugged.

Mr. Patel, United Republic of Tanzania:

I want to wish GlobeCore success in the future and I think we will maintain our cooperation for many more years. May you have as many successful products and new developments as possible.

About colloid mill manufacturer

GlobeCore is the manufacturer of the Globecore® high speed emulsifying machines. All equipment is certified. Quality control is ISO 9001:2001 certified, certificate No UA.2.039.02021-06. The company employs more than 200 highly qualified staff. The manufactured products are of modern design and high capacity due to constant improvements introduced by the engineers.

The СLM colloid mill is specifically designed for production of highly stable colloid solutions, superfine suspensions, mixes and emulsions. The mill utilizes wet grinding principle, where results are produced by the gap between the teeth of rotor and stator.

Your product manager at GlobeCore:

Sergey Mezhievskiy

A responsible and dedicated person. He will accompany you through all stages from placing the order to shipment of the product. Experience in industrial sales and in finding solutions for real issues in the field allows him to fully understand you, select the appropriate equipment model and ensure timely delivery.

Skype: mezhievskiy

Our location:

The production facility is located in Oldenburg-Eversten, Germany, Edewechter Landstraße 173.