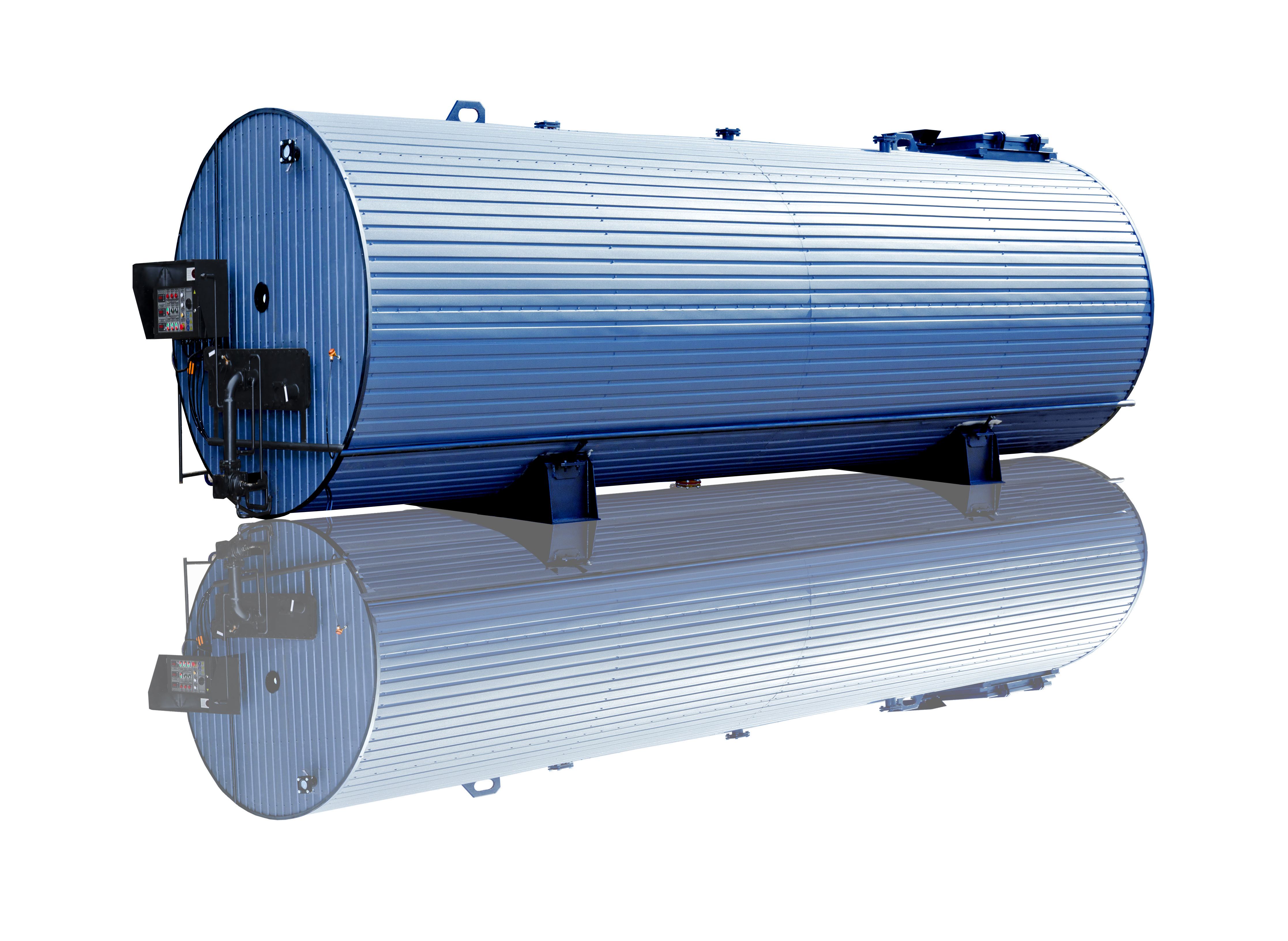

Horizontal Bitumen Storage Units

Storage and preparation of bitumen on site has a number of advantages for your business enterprise. The availability of bitumen storage and bitumen boilers allows for the creating and replenishing of your own reserves of material without fear of market fluctuations and unstable supply that can disrupt your business operations. There are various special containers for the storage and heating of bitumen.

GlobeCore offers equipment that is optimally suited to the technical features of your business.

The basic purpose of a bitumen complex is bitumen storage. Its main advantage is that it can be used both as a storage container of bitumen emulsion and as a container for heating bitumen.

Bitumen storage is a “reservoir inside of a reservoir”, i.e. made of metal sheets 6 mm thick, sheathed insulation contained in an “Isover.” (Thermal Insulator)

Horizontal bitumen tanks can be used by businesses engaged in the production of asphalt for asphalt roadways, basement waterproofing and concrete structures, soft asphalt based roofs, primer manufacturing, mastics and hydro glass.

The design department at GlobeCore has developed specific solutions for different companies in the construction industry. Thus, depending on the nature of the enterprise and on the technology and the materials used, you can choose the most efficient model with minimal requirement of resources and facilities.

For example, diesel, heating oil, or gas can be used when you install the burner with flame tubes. Thermal oil can be used as an alternative heating fuel. In that case, the heating is carried out in a special heating boiler.

An MTG-generator with a capacity of 400 thousand kCal can be used for the same purpose. This type of equipment is manufactured by our factory and can be delivered to the customer along with the horizontal bitumen storage unit. Its main advantage over conventional models is the increased power it provides for speed and performance.

GlobeCore’s years of experience has led our engineers to create and implement technical solutions for businesses for any process regardless of complexity. Upon the customer’s request, the bitumen storage units can be made in two different construction designs depending on which substance is used for heating. The volume of bitumen storage may vary from 28m^3 to 30m^3 depending on the presence or absence of a flame tube.

Recently, industrial grade factories have followed a trend of using equipment that runs on the previously mentioned thermal oil. The increased trend in the use of thermal oil is due to its efficiency, environmental friendliness and its ability to maintain of all the necessary performance characteristics of the bitumen during the heating process.

The advantage, of heating a horizontal bitumen storage unit with thermal oil, over other storage units that do not use thermal oil, is the uniform and consistent heating of the materials. The tube temperature does not exceed the boiling point of the bitumen therefore, it cannot overheat the materials. Furthermore, the heat produced by thermal oil can be used for heating all of the bitumen storage units consisting of at least 3-4 horizontal tanks.

Using other sources of heat other than thermal oil may cause the bitumen to become overheated and fallout as sludge to the bottom of the storage unit and lose its desired properties. To avoid this, you need to constantly monitor the processes occurring inside the tanks. After use, it will be necessary to drain the bitumen and clean the tanks. It is also worth noting that the bitumen cannot be drained completely however since it should at least cover the flame tubes. Despite these shortcomings, this design has been used in many enterprises that use gas or other types of fuels.

GlobeCore’s design department and engineers are constantly improving the technology by eliminating all kinds of disadvantages through the introduction of superior modern technologies and practical devices. Since bitumen is a relatively viscous substance, the design of the horizontal storage unit has a special stirrer consisting of three pieces that accelerate the mixing of hot and cold layers of the heated material.

A distinctive feature separating our tank for storing and heating bitumen from other industry designs is that its dimensions are very similar to that of a sea container. Due to this similarity in size, we are able to deliver a GlobeCore horizontal bitumen storage tank via sea transport to any port in the world.

This GlobeCore model is considered to be portable. When transporting the container with the gas burner and flame tube, the burner and flame tube can be protected by removal and placement into special registers.

In order to place the equipment back into service after relocation, you will need to install the flame tube into its original position in according with the service manual that is part the technical instructions and documentation supplied with the unit.

Horizontal bitumen storage units may also include a special pump for feeding the bitumen that is also manufactured and supplied by GlobeCore.

The customer can order the whole bitumen complex that has been appropriately tested and certified.

Comparative characteristics and technical data of bitumen storage versions:

|

Characteristics |

Bitumen storage with burner |

Bitumen Storage running on thermo oil |

| The total volume of the boiler in m3 |

32 |

32 |

| The working volume of the boiler in m3 |

28 |

28 |

| Type of heating thermo |

Fire |

Thermal oil |

| Set power in kW |

23 |

|

| The parameters of the burner: | ||

| – Nominal power in kW |

430 |

|

| – Maximum power in kW |

540 |

|

| – Fuel |

Natural gas G20 |

|

| – Gas pressure |

20 bar |

|

| – The maximum gas flow rate in m3/hr |

38 |

|

| The parameters of the electric current |

380V/50Hz |

380V/50Hz |

| Dimensions in mm | ||

| – Length |

11750 |

11750 |

| – Width |

2100 |

2100 |

| – Height |

2500 |

2500 |

| Weight in kg no more than |

12700 |

12700 |

Frequently Asked Questions:

1. Should the bitumen storage be constantly filled?

The answer depends on the type of storage container.

The advantage of using thermal oil for heating is that the bitumen can be half-full or drained completely and the container will remain in working condition.

In the case of the flame tubes, it is not recommended to drain material below the tube level since unwanted bitumen burning may occur. This can lead to the entire machine becoming engulfed in flames. For reheating it is necessary to fill the container with new bitumen.

2. How to control the filling of the bitumen storage Unit? What kind of safety measures are there?

The unit has a system of special devices that include:

- Leveling sensors (located on the perimeter of the installation);

- Temperature sensors for the upper and lower layers of bitumen;

- Overflow sensor (at the top of storage to improve the accuracy of measurements);

- Backup leveling sensor;

- Overflow pipe.

When a leveling sensor is triggered it switches off the pump that feeds the material into the bitumen tank. For emergencies, there are special holes for quick drainage of bitumen.

3. How is the machine delivered to the client?

The unit is delivered to the client in a partially disassembled state.

It is necessary to deliver the gearboxes and the burner separately. Our engineers are able to come to the delivery site and assemble the model. Ladders used for installation are removable.

4. Terms of warranty?

Warranty period is 12 months from date of shipment from the supplier’s warehouse. The manufacturer guarantees the normal and stable operation of the system under in accordance with proper guidelines, proper installation, proper operation, proper maintenance, proper transportation and proper storage.

5. How many operators are necessary for the management of this installation?

A minimum crew of two people is required.

6. How long can the material stay in the bitumen storage?

The safe/appropriate storage time length depends on the brand and manufacturer.