Catalysts are special substances that speed up chemical reactions while remaining unchanged themselves. Unlike other reagents, catalysts remain unchanged when the process is finished. The reaction proceeds more slowly or does not proceed at all without catalysts. The essence of catalytic reactions can be summarized as follows: First, the catalyst reacts with original substance. An intermediate compound undergoes changes and then divides into a product and a catalyst. This process repeats in the cycle up to a million times.

There are homogeneous and heterogeneous catalysts. Homogeneous catalysts are in one phase with reacting substances and heterogeneous catalysts form an independent phase, being separated from the phase of reacting substances by a boundary line.

Acids and bases are often used as homogeneous catalysts and metals, such as oxides and sulfides are used as heterogeneous ones. In biochemical reactions, enzymes act as catalysts. For industrial purposes, homogeneous catalysts are used to obtain alcohols, nitrobenzene and other nitro compounds, such as acetic acids, aldehydes, and medicines. The main difference between homogeneous catalysis and heterogeneous catalysts is that homogeneous catalysts require the reactions to proceed in the whole mixture. Only in this case it is possible to reach the highest levels of catalyst’s efficiency.

In practice, it may be troublesome to choose equipment that is able to provide an even distribution of catalyst throughout the whole reagent. GlobeCore colloid mills meet all the requirements listed above. GlobeCore Colloid mills are designed to obtain high-stable colloidal solutions, fine suspensions, mixtures, and emulsions.

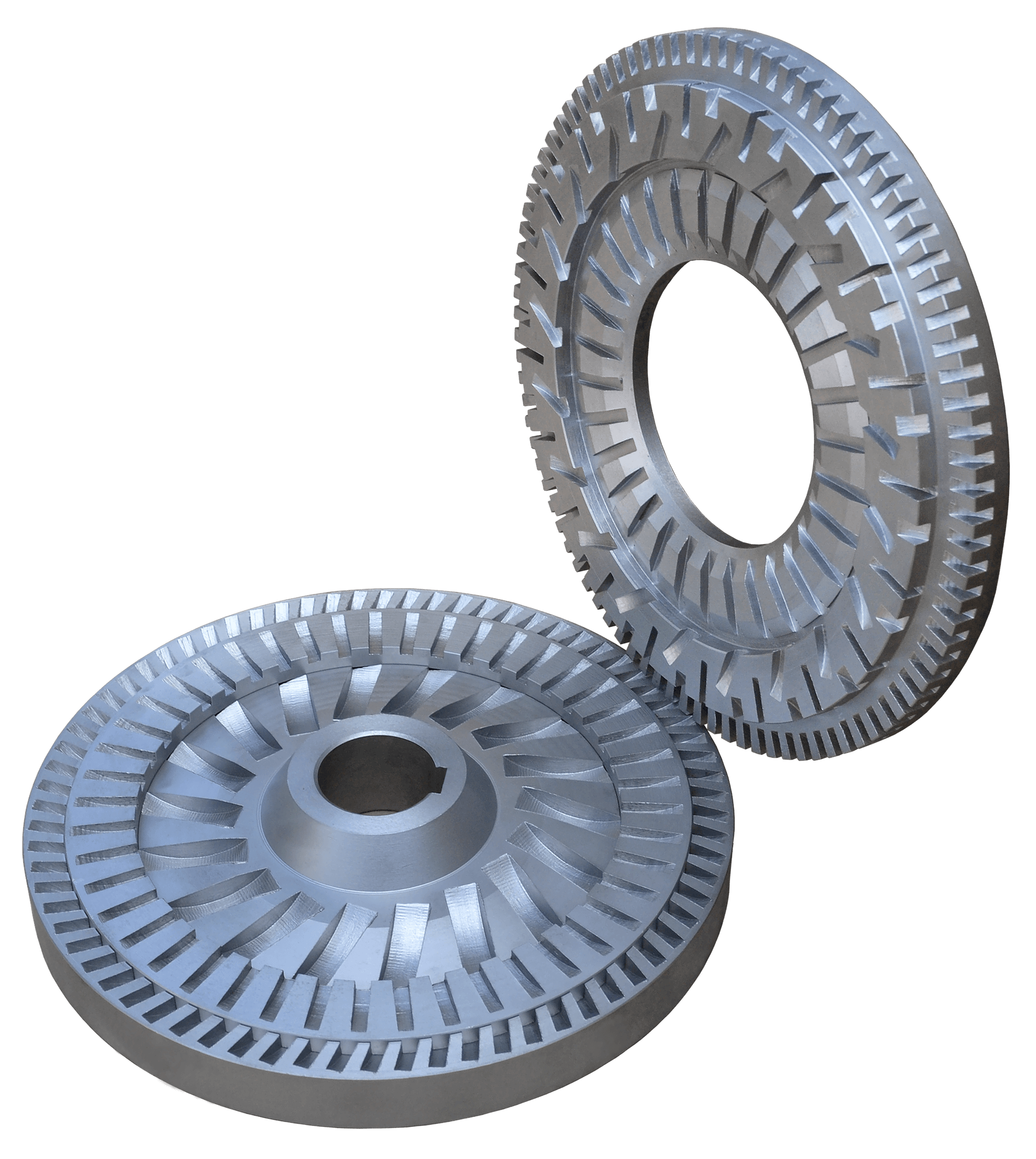

The operational principle of colloid mills is based on centrifugal force and high relative speed between a rotor and a stationary stator that provide an even distribution of catalyst throughout the whole reagent. As a result, the final substance becomes homogeneous that makes it possible to reach the highest level of catalyst’s efficiency.

GlobeCore produces both industrial (CLM-4, CLM-18, CLM-22) and laboratory models of colloid mills (CLM-05.3).

Colloid mills for industrial purposes are used to increase the efficiency of technological processes such as the production of medicines, acetic acid, aldehydes, alcohols, nitrobenzene, and terephthalic acid.

Laboratory models of colloid mills are used in special chemical laboratories to explore new catalysts or to find new application areas of existing ones.